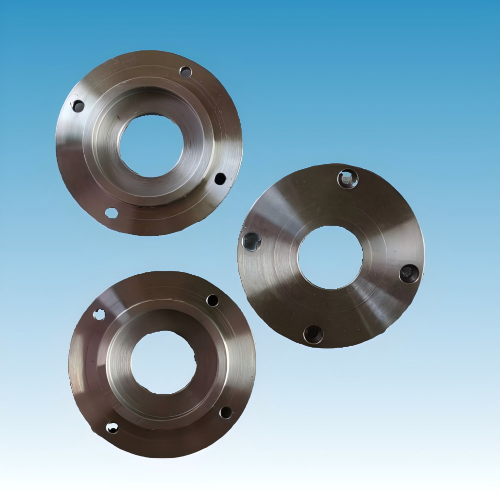

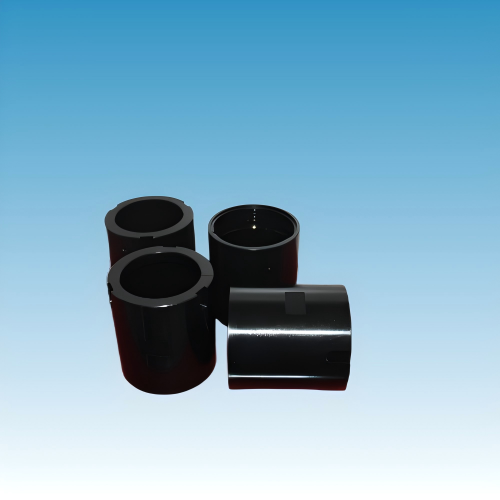

联轴器纺织机械精密原厂备件

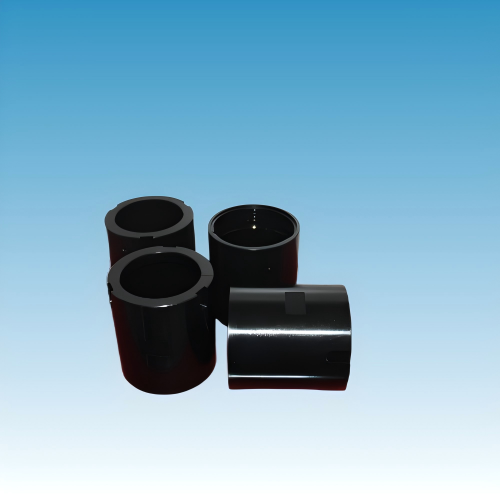

联轴器 纺织机械配件 轴 纺织设备配件套筒,厂家直销,价格优惠,精密原厂配件

SC205FZ2024

一个 联轴器 对于纺织机械来说 机械装置 连接两根旋转轴,高效传输动力,同时补偿错位并减少振动。这些联轴器确保 运行平稳、精确 纺织机械需要高速和连续运动才能生产出优质的织物。

名称: 联轴器

型号:SC205FZ2024

材质:按照您的要求

最小起订量:根据您的要求

交货:根据您的数量

样品:提供样品

产地:中国浙江

服务:OEM ODM 定制

优势:专业团队 高品质

为什么联轴器对于纺织机械如此重要?

纺织机械用联轴器是一种连接两根旋转轴的机械装置,用于高效传输动力,同时补偿轴心偏差并减少振动。这些联轴器确保纺织机械平稳、精确地运行,而纺织机械需要高速、连续的运动才能生产出高质量的织物。

纺织机械中联轴器的关键功能

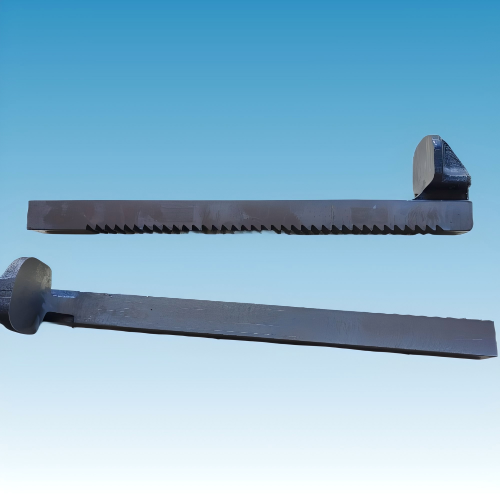

动力传输 – 将旋转运动从电机传输至机器的不同部件。

补偿错位 – 可适应因安装错误或操作压力而导致的轻微轴错位。

吸收冲击和振动 – 减少连接部件的机械应力,确保更长的机器寿命。

实现平稳运行 – 最大限度地减少扭矩波动,实现一致的纺织加工。

提高机器效率 – 确保稳定运行,减少停机时间并提高生产率。

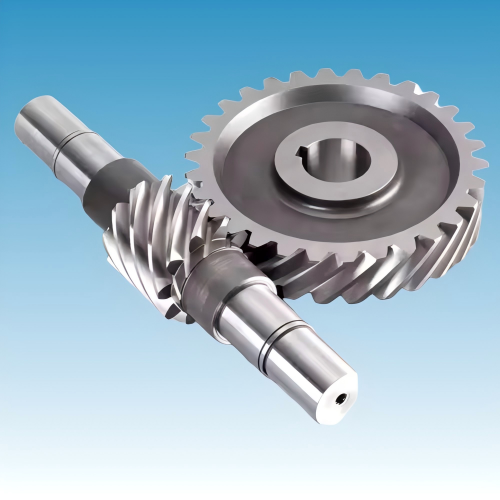

纺织机械中使用的联轴器类型

弹性联轴器 – 吸收错位和振动,常用于纺织纺纱和织布机。

刚性联轴器 – 当需要精确的轴对中时使用,适用于高速纺织工艺。

齿式联轴器 – 处理重型纺织应用中的高扭矩负载。

膜片联轴器 – 为精细纺织操作提供高精度和耐用性。

弹性联轴器 – 使用橡胶或聚合物元件来减轻纺织机械的振动。

联轴器在纺织工业中的应用

纺纱机 – 将动力传输至纺锤以进行纱线生产。

织机 – 确保经线和纬线同步运动。

针织机 – 帮助控制精确的针头运动以形成织物。

染整机械 – 在织物处理过程中保持平稳运行。

印刷机 – 支持纺织品印花的精确滚筒运动。

为什么联轴器对于纺织机械如此重要?

减少磨损 – 防止机器零件受到过大的机械应力。

提高机器寿命 – 提高耐用性并降低维护成本。

确保高速性能 – 对于大规模纺织品生产至关重要。

提高织物质量 – 平稳运行可实现均匀、高质量的纺织品输出。

结论

联轴器在纺织机械中起着至关重要的作用,它确保 高效动力传输、减少振动并提高机器性能. 选择正确的耦合类型可以增强 机器寿命、生产率和织物质量使其成为纺织工业的重要组成部分。

联轴器是用于 连接旋转轴 在各种工业和机械应用中。它们被广泛购买 制造商、工业工厂、机械供应商和工程公司 确保动力传输平稳、机器高效运行。

神驰科技有限公司是一家专业 OEM机械工厂 位于中国浙江温岭。主要业务包括数控车削和铣削零件、数控加工中心零件等。我们可以完成模具产品、标志定制和精加工服务,包括喷砂、粉末喷涂、阳极氧化、电镀、抛光和激光蚀刻。

© 神驰公司版权所有