- WENLING ZHEJIANG CHINA

- [email protected]

- 86 18958695512

- Home

- PRODUCT

- Other products components

- Worm Gear Set Precision Rotavator Wheel best Component Shaft

Worm Gear Set Precision Rotavator Wheel best Component Shaft

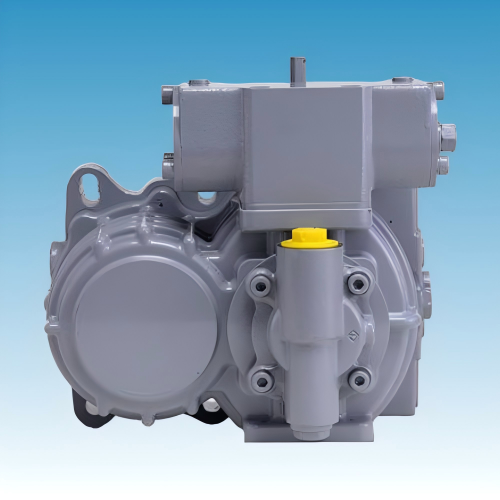

As a professional CNC machining factory, we specialize in the production of high-performance worm gear sets that deliver smooth, controlled power transmission across industrial machinery. Whether you’re an OEM manufacturer, importer, or distributor, our Worm Gear Motor Sets are built to meet the highest standards of precision, durability, and customization.

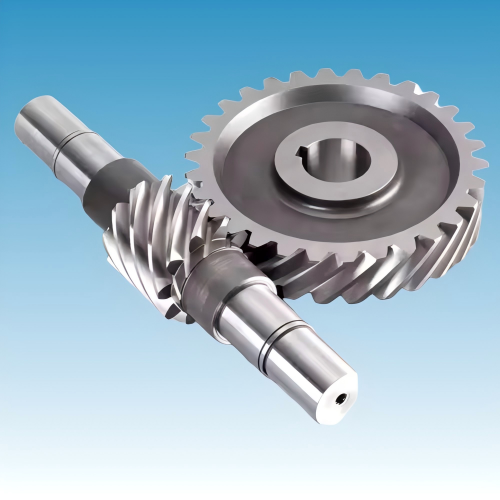

Our Worm Gear Sets consist of a hardened steel worm and a matching worm wheel gear, precision-machined to ensure seamless engagement. These components are designed for high reduction ratios, quiet operation, and maximum torque transmission in limited spaces.

Material Options: 45# steel, stainless steel, bronze, and custom alloys Module Range: M0.5 to M8 Diameter: Up to 500mm Precision: DIN 6–8 grade, CMM-tested Application: Worm Gear Motor Set, linear actuators, conveyor systems, automation drives

NAME: Worm gear set

MODEL:SC205GR4124

MATERIAL: FOLLOW YOUR REQUIREMENT

MOQ: AS YOUR REQUIREMENT

DELIVERY: ACCORDING TO YOUR QUANTITY

SAMPLE: SAMPLE OFFERED

ORIGIN PLACE: ZHEJANG CHINA

SERVICE: OEM ODM CUSTOMIZED

ADVANTAGE: PROFESSIONAL TEAM HIGH QUALITY

Precision and Power: Discover Our Worm Gear Set Solutions for Global Industries

In the evolving landscape of industrial transmission components, worm gear sets remain a cornerstone solution for applications that require compact design, smooth torque transmission, and enhanced mechanical advantage. At [Your Company Name], a leading CNC machining factory, we specialize in manufacturing high-precision worm gear sets tailored to a wide array of global industries, including textiles, automation, printing, automotive, robotics, and material handling.

This article introduces our full capability in producing worm gear motor sets, worm wheel gears, and custom CNC worm gears, and showcases why global buyers from Europe, North America, Southeast Asia, and the Middle East continue to rely on us for critical motion and power transmission needs.

1. What Is a Worm Gear Set?

A worm gear set typically consists of two components: the worm (a screw-like shaft) and the worm wheel (a specially designed gear). When the worm rotates, its threads mesh with the gear teeth of the worm wheel, transmitting motion at a right angle. This configuration offers significant advantages:

High reduction ratios in a compact form

Self-locking properties for safety-critical applications

Smooth and quiet operation even under high load

Reliable torque transmission

Our worm gear motor sets are ideal for applications where space constraints and precision motion control are priorities.

2. Manufacturing Excellence: Our CNC Worm Gear Factory Strength

Facility Overview

Our factory covers over 12,000 square meters and is equipped with state-of-the-art CNC lathes, gear hobbing machines, five-axis machining centers, gear testers, and CMM quality inspection systems. With a monthly capacity of 50,000+ worm gear components, we serve high-demand buyers with scalable production.

Material Expertise

We select only high-grade materials such as:

20CrMnTi and 42CrMo for hardened steel worm shafts

Bronze, aluminum-bronze, and phosphor bronze for worm wheels

Optional nylon composite worm gears for lightweight, quiet operation

All materials are traceable and comply with RoHS and REACH environmental standards.

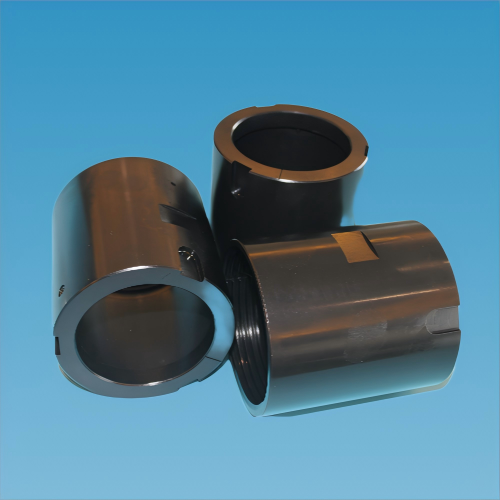

Heat Treatment & Surface Finish

To guarantee the durability and wear resistance of our products, we implement:

Carburizing & Quenching for worm shafts

Hobbing precision grade: DIN 6 or higher

Polishing, black oxide, anodizing, or nickel plating as per customer requirements

Quality Control You Can Count On

Each high precision worm gear set undergoes:

Runout testing, gear meshing tests, and surface hardness checks

100% dimensional inspection using CMM, gear measuring centers, and profile projectors

Complete QA documentation and batch traceability

Our factory is ISO 9001 certified and adheres to strict international quality standards.

3. Product Portfolio: Tailored to Your Industry

Whether you are a distributor, OEM, or equipment integrator, our worm gear product range meets diverse requirements:

A. Standard Worm Gear Motor Sets

Output torque: 10 Nm to 1500 Nm

Ratios: 1:10 to 1:80

Right-angle shaft design

Available in both metric and inch sizes

Used in automation lines, conveyors, lift systems, and mixers

B. Custom CNC Worm Gears

We produce custom CNC worm gears according to 2D drawings or 3D models in formats like STEP, DWG, or IGS.

Custom teeth profiles (ZA, ZI, ZN)

Single or double lead worm

Axial and radial tolerance control within 0.01 mm

Delivered with RoHS-compliant and REACH-certified coatings

C. Worm Wheel Gears

We specialize in precision worm wheel gear production using:

Bronze, brass, or steel

Gear diameter: 30 mm to 500 mm

Tooth count from 10 to 150

Applications: textile machines, servo drives, and printing presses

4. Application Fields: Trusted in Critical Industries

Our worm gear sets are used in demanding industries across the globe:

Textile Industry

Used in yarn winding, spinning equipment, and automatic looms, our worm gears offer quiet performance and long service life.

Printing & Packaging

Our worm wheel gears are used in printing presses, folder-gluers, and labeling machines, where consistent speed and precision are key.

Automotive Components

OEMs use our CNC worm gear sets in seat recliner systems, electric tailgate openers, and throttle actuators.

Automation & Robotics

Compact, lightweight, and high-precision worm gear motor sets serve robotic arms, SCARA robots, and AGV drive modules.

Medical & Laboratory

Low-noise, compact worm gear drives are ideal for medical beds, patient lifts, and lab sample handlers.

5. Why International Buyers Choose Us

We are not just a gear supplier—we are your technical partner. Here’s what sets us apart:

| Advantage | Your Benefit |

|---|---|

| Complete In-house Production | Faster delivery, lower cost, tight QC |

| Custom Engineering | From prototyping to mass production |

| International Logistics Expertise | CE-certified, export-ready documentation |

| Rapid Response Team | English-speaking engineers and real-time support |

| Strong After-Sales Network | Spare parts within 72 hours, service in your time zone |

6. Global Case Studies

Germany-Based Textile Machinery OEM

We have supplied worm gear motor sets to a German client for their automatic winding machines since 2017. Our parts helped reduce motor overheating and increased production uptime by 18%.

USA Printing Equipment Buyer

Our custom CNC worm gears have been used in their folding equipment. Tolerance holding of ±0.01 mm ensured high print alignment. Annual orders exceed 15,000 units.

Southeast Asia Conveyor Manufacturer

The client integrated our worm wheel gear assemblies into their belt conveyors. Our bronze gears proved more durable than aluminum competitors, reducing service calls by 30%.

7. OEM & ODM Services

We welcome OEM and ODM orders. Whether you’re looking for:

Custom logo engraving

Unique shaft design

Integrated worm motor with planetary stages

Kits with mounting hardware and seals

Our R&D team will support your design from concept to final production, ensuring compatibility and performance.

8. Certifications & Exports

Our worm gear sets comply with the following certifications:

ISO 9001:2015

CE Compliance for Machinery Directive

Material certifications (RoHS, REACH, SGS)

Export to 35+ countries including Germany, USA, Canada, Japan, Brazil, Turkey, India, and South Africa

We provide export documentation, including:

HS codes

Certificates of origin

Inspection reports

Packing lists and invoices with buyer logo if needed

Conclusion: Let’s Build Long-Term Success Together

If you’re a buyer of worm gear sets, a sourcing manager for CNC worm gear components, or a developer of custom power transmission solutions, we invite you to partner with us.

At shenchi, we combine deep industry expertise, modern CNC precision, and a customer-first attitude to bring your designs to life. From Worm Gear Motor Sets to Worm Wheel Gears, we deliver components that keep your machinery—and your business—moving forward

Shenchi technology co.,is a professional OEM machinery factory located in Wenling zhejiang,China. The main business includes CNC turning and milling parts, CNC machining center parts, etc.We can complete the mold product, logo customization and finish services including sandblasting, powder coating, anodizing, electroplating, polishing and laser etching.

© Shenchi Company All Rights Reserved.