- WENLING ZHEJIANG CHINA

- [email protected]

- 86 18958695512

- Home

- PRODUCT

- Printing machinery components

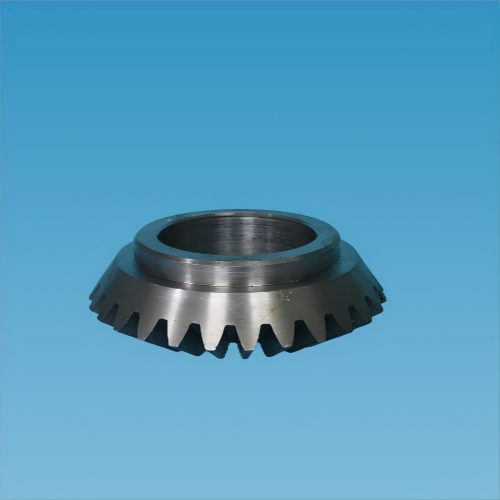

- Gear shaft Drive turbine for printing Machinery spare parts

Gear shaft drive turbine for printing machinery spare parts

Gear shaft Drive turbine for printing Machinery spare parts Best Price Custom Industrial Non-Standard Gear set spare Parts For offset Printing Machine worm Shaft Drive Pinion gears

SC205YS2001

Gear Shaft Drive Turbine for Printing Machinery is a mechanical system used to transfer rotational power from a gear shaft to a turbine in printing machines. This system plays a crucial role in the operation of printing presses and related equipment by providing the necessary motion and speed control for various parts of the machine. It ensures that the printing process is smooth, precise, and efficient.

NAME: GERA SHAFT,DRIVE TURBINE

MODEL: SC205YS2001

MATERIAL:STEEL,COPPER

MOQ: AS YOUR REQUIREMENT

DELIVERY: ACCORDING TO YOUR QUANTITY

SAMPLE: SAMPLE OFFERED

ORIGIN PLACE: ZHEJANG CHINA

SERVICE: OEM ODM CUSTOMIZED

ADVANTAGE: PROFESSIONAL TEAM HIGH QUALITY

Functions of Gear Shaft Drive Turbine in Printing Machinery

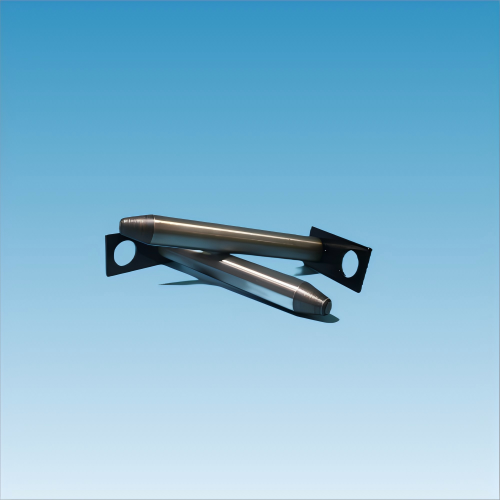

Gear Shaft:

- The gear shaft is a central component in this system. It is responsible for transmitting rotational force (torque) from a power source, typically an electric motor or engine, to other parts of the machine. The gear shaft is connected to gears that mesh with other gears or mechanical components, thereby driving specific functions within the printing press.

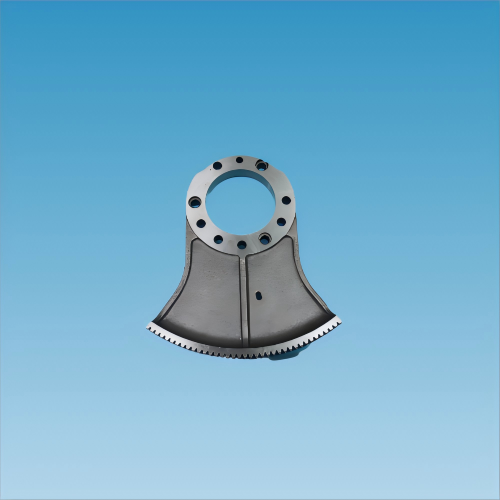

Turbine:

- A turbine in this context is typically used as a high-speed rotating device that converts energy from the gear shaft into mechanical motion. It may be used to control or drive the speed of rollers, impression cylinders, or other key parts of the printing machine. In some systems, a turbine may be used in combination with a clutch or gearbox to adjust the speed and direction of motion as needed.

- The turbine usually works in conjunction with other gears or mechanisms to provide smooth power transmission, ensuring that the different parts of the printing machine operate at the correct speeds.

Function in Printing Machinery:

- Speed and Torque Control: The gear shaft drive turbine helps regulate the speed and torque applied to various components of the printing press, such as the rollers, cylinders, and paper feed mechanisms. This ensures that the printing process operates at a consistent and precise speed, allowing for high-quality prints.

- Precise Synchronization: Printing presses often require precise timing between different machine components. The gear shaft drive turbine ensures that the components, like ink rollers, printing plates, and impression cylinders, work in perfect sync to deliver accurate and consistent prints.

- Power Distribution: The turbine helps distribute power across different parts of the printing machine. It allows for the effective distribution of energy to various units such as the ink distribution system, drying units, or pressing sections of the printing press.

Applications in Printing Press:

- Offset Printing: In offset printing presses, gear shaft drive turbines are often used to control the rotational speed of various cylinders (such as the blanket cylinder and impression cylinder). These turbines help manage the printing and inking process, ensuring that the press runs smoothly and efficiently.

- Flexographic Printing: In flexographic printing presses, gear-driven turbines help regulate the speed of the anilox rollers and print cylinders. The consistent speed ensures that ink is transferred evenly and accurately to the printing substrate.

- Gravure Printing: In gravure printing presses, gear shaft drive turbines manage the speeds of the engraved cylinders, ensuring high-speed operation with the required precision.

Materials and Durability:

- The gear shaft and turbine components are typically made of durable materials such as steel, alloy steel, or hardened steel to withstand the high-speed operations and heavy loads of printing machines. The materials used are resistant to wear, corrosion, and heat, ensuring longevity and reliable performance over time.

Advantages of Gear Shaft Drive Turbines in Printing Machinery:

- Precision: The gear shaft drive turbine system helps ensure that the printing machine components operate in precise synchronization. This precision is crucial for achieving high-quality prints and consistent results across large print runs.

- Speed Control: The system allows operators to adjust the speed of various components, which is important for adapting to different printing tasks (e.g., printing on different substrates or adjusting ink flow).

- Energy Efficiency: By using gears and turbines, the system can efficiently transfer power from the motor to the required components, reducing energy consumption and ensuring the efficient operation of the press.

- Reduced Wear and Tear: By controlling the flow of power and reducing the number of mechanical components that could wear out from excessive force, the gear shaft drive turbine system can help extend the life of the printing machinery.

- Smooth Operation: The smooth transmission of power helps prevent jerky movements or imprecise actions within the press, ensuring a steady and consistent print quality.

Summary:

A Gear Shaft Drive Turbine for Printing Machinery is an essential power transmission system used in various types of printing presses. It connects the power source to key parts of the printing press, such as rollers, cylinders, and ink distribution systems, to ensure smooth, synchronized, and precise operation. The system helps control speed, torque, and power distribution, ensuring high-quality prints and efficient performance. The use of durable materials and precision components ensures the longevity and reliability of the system in demanding printing environments.

Shenchi technology co.,is a professional OEM machinery factory located in weneling zhejiang,China. The main business includes CNC turning and milling parts, CNC machining center parts; etc.We can complete the mold product, logo customization and finish services including sandblasting, powder coating, anodizing, electroplating, polishing and laser etching.

©2024. Shenchi Company All Rights Reserved.