- WENLING ZHEJIANG CHINA

- [email protected]

- 86 18958695512

- Home

- PRODUCT

- Textile machinery components

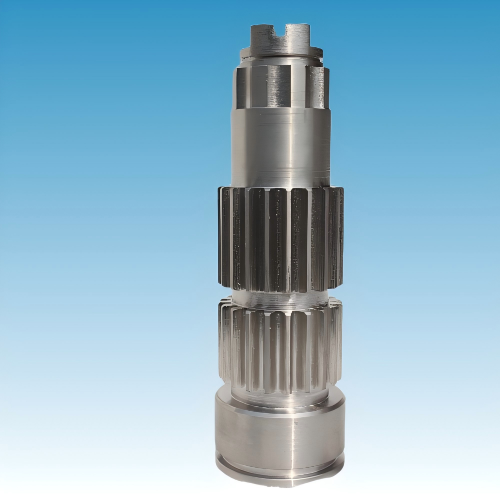

- Eccentric Shaft Custom Spline Shaft CNC machinery OEM Shaft

Eccentric Shaft Custom Spline Shaft CNC Machinery OEM Shaft

Eccentric Shaft Custom Spline Shaft CNC Factory Machining Steel Stainless Steel OEM Shaft Manufacturer for machinery spare Parts & Components

SC205FZ5008

Eccentric shaft is a mechanical component used to convert rotary motion into reciprocating motion. It has an off-center (eccentric) positioning relative to its rotational axis, creating an oscillating or reciprocating motion when rotated.

NAME:Eccentric Shaft

MODEL: SC205FZ5008

MATERIAL:STEEL

MOQ: AS YOUR REQUIREMENT

DELIVERY: ACCORDING TO YOUR QUANTITY

SAMPLE: SAMPLE OFFERED

ORIGIN PLACE: ZHEJANG CHINA

SERVICE: OEM ODM CUSTOMIZED

ADVANTAGE: PROFESSIONAL TEAM HIGH QUALITY

Key Features of an Eccentric Shaft

It is a mechanical component with its rotational axis positioned off-center from its main body. This unique design allows the shaft to create variable motion patterns, such as oscillating, reciprocating, or elliptical motion, making it ideal for applications that require precise movement control.

they are widely used in automotive engines, industrial machinery, vibrating screens, textile machines, and medical devices due to their ability to convert rotary motion into controlled linear or oscillating motion.

Key Features of an Eccentric Shaft

✔ Off-Center Rotation – Unlike a standard shaft, an eccentric shaft rotates around an axis that is not in the center, creating non-uniform motion.

✔ High-Strength Materials – Made from hardened steel, alloy steel, stainless steel, or aluminum to handle high loads and resist wear.

✔ Efficient Motion Conversion – Used in applications where rotary motion needs to be converted into reciprocating or oscillating motion.

✔ Versatile Applications – Found in automotive, industrial, textile, and medical equipment for precise movement control.

✔ Durable & Reliable – Designed to operate under continuous stress and heavy-duty conditions.

How an Eccentric Shaft Works

- Rotational Motion Begins – The eccentric shaft is connected to a power source, such as an engine or motor, and starts rotating.

- Off-Center Motion – Since the axis of rotation is not centered, the shaft generates irregular motion instead of a uniform spin.

- Motion Transfer – The non-uniform rotation is transferred to connected mechanical components, enabling vibration, oscillation, or controlled movement.

For example:

- In Wankel rotary engines, eccentric shafts help control rotor movement.

- In vibrating screens, they generate controlled shaking motion for material processing.

- In textile machines, they enable smooth weaving and fabric handling.

Applications

Automotive Industry

- Used in Wankel rotary engines, camshafts, and crank mechanisms to regulate movement.

- Essential for valve control, fuel injection, and timing adjustments.

Industrial Machinery

- Found in metal stamping machines, punching presses, and rolling mills for force distribution and smooth motion.

Vibrating Equipment

- Used in vibrating screens, conveyors, and sorting machines to generate controlled vibration for material handling.

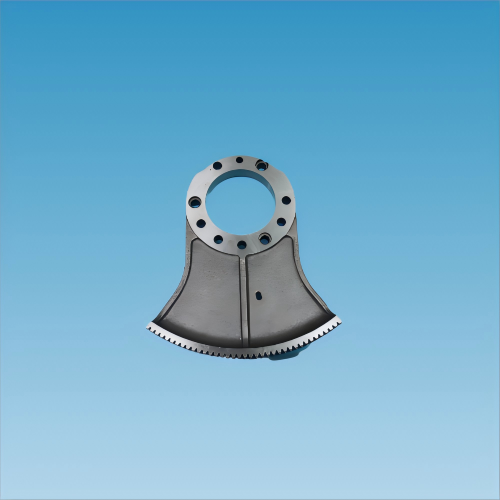

Textile & Printing Machines

- Ensures precise fabric movement, print alignment, and controlled motion in textile looms.

Medical & Laboratory Equipment

- Applied in robotic surgical tools, MRI machines, and diagnostic devices for precise mechanical movement.

Advantages

✔ Precise Motion Control – Converts rotary motion into controlled oscillation or reciprocation.

✔ Durability & Strength – Built to withstand high mechanical loads and stress.

✔ Versatile Functionality – Used in a wide range of industrial, automotive, and medical applications.

✔ Increased Efficiency – Helps optimize motion transfer in machinery, improving overall performance.

Conclusion

An eccentric shaft is a crucial mechanical component that plays a significant role in motion control, power transmission, and mechanical efficiency. Its unique off-center design makes it indispensable in engines, industrial machinery, vibrating systems, and high-precision equipment.

With advancements in engineering and materials, eccentric shafts continue to enhance the performance and reliability of modern mechanical systems

Shenchi technology co.,is a professional OEM machinery factory located in weneling zhejiang,China. The main business includes CNC turning and milling parts, CNC machining center parts; etc.We can complete the mold product, logo customization and finish services including sandblasting, powder coating, anodizing, electroplating, polishing and laser etching.

©2024. Shenchi Company All Rights Reserved.