- WENLING ZHEJIANG CHINA

- [email protected]

- 86 18958695512

- Home

- PRODUCT

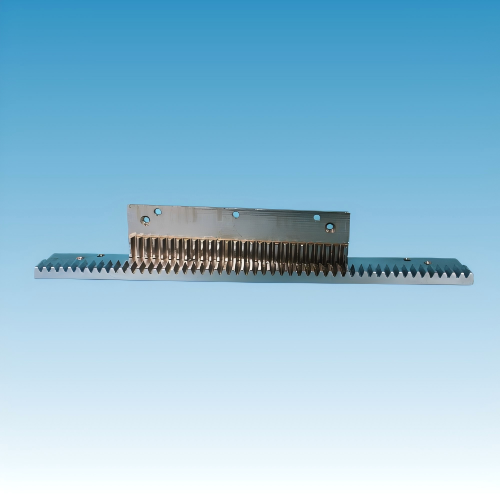

- Other products components

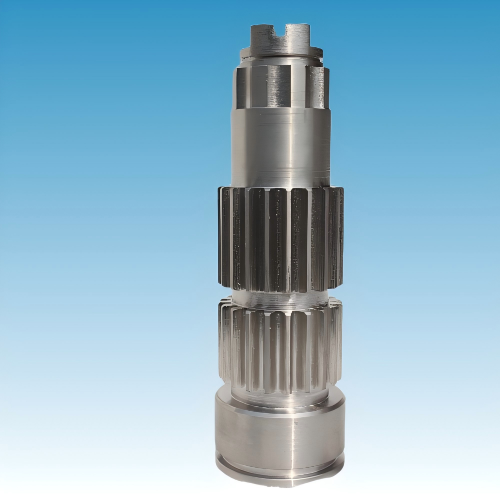

- Brass Drive Gear Custom-Made Precision CNC Machinery Part

Brass Drive Gear Custom-Made Precision CNC Machinery Part

Brass Drive Gear Custom-Made High Precision CNC Machining /turning /milling 5Axis Gearbox Assembly Gear Manufacturing 15-30 Teeth Metal Steel For Machinery Part

brass drive gear is a mechanical component made of brass, designed to transmit motion and torque between machine parts. It is commonly used in various applications, including automotive systems, industrial machinery, household appliances, and precision instruments. Brass drive gears are known for their durability, corrosion resistance, and smooth operation, making them ideal for applications that require reliable and long-lasting performance.

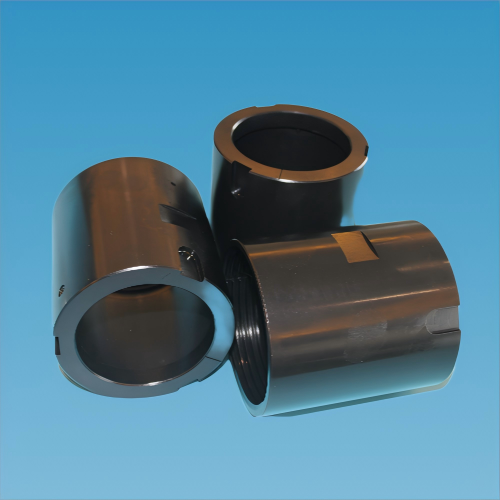

NAME:CONSTRUCTION SPATR PARTS

MODEL: SC205GC4008

MATERIAL:STEEL

MOQ: AS YOUR REQUIREMENT

DELIVERY: ACCORDING TO YOUR QUANTITY

SAMPLE: SAMPLE OFFERED

ORIGIN PLACE: ZHEJANG CHINA

SERVICE: OEM ODM CUSTOMIZED

ADVANTAGE: PROFESSIONAL TEAM HIGH QUALITY

Applications of Brass Drive Gears

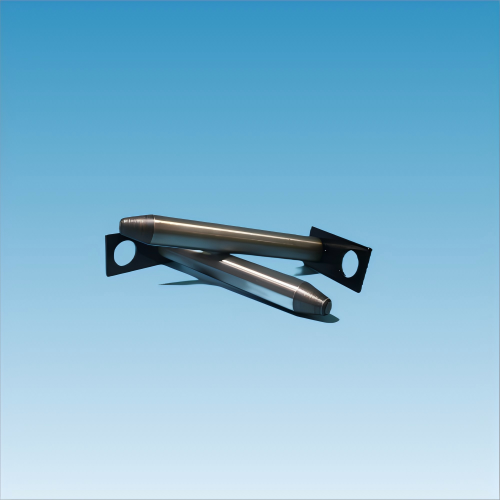

Eccentric Shaft: Definition & Applications

An eccentric shaft is a mechanical component used to convert rotary motion into reciprocating motion. It has an off-center (eccentric) positioning relative to its rotational axis, creating an oscillating or reciprocating motion when rotated.

Key Features of Brass Drive Gears

Material Composition:

- Made from brass, which is an alloy of copper (Cu) and zinc (Zn).

- Some brass gears contain additional elements like lead (Pb) for better machinability.

- Brass provides a good balance of strength, wear resistance, and corrosion resistance.

High Corrosion Resistance:

- Brass gears are highly resistant to rust and oxidation, making them suitable for humid or marine environments.

- They are commonly used in outdoor equipment, water pumps, and marine applications.

Smooth & Quiet Operation:

- Brass gears generate less noise and friction compared to steel gears.

- They are often used in precision instruments, watches, and household appliances where noise reduction is important.

Good Machinability:

- Brass is easy to machine, allowing for precise manufacturing of gear teeth.

- This results in high-quality, finely detailed gears with smooth engagement.

Moderate Strength & Durability:

- While not as strong as steel gears, brass drive gears offer adequate strength for light-to-moderate load applications.

- Ideal for low-speed and medium-duty mechanical systems.

Self-Lubricating Properties:

- Brass gears have natural lubrication properties, reducing wear and friction.

- This makes them a good choice for applications requiring low-maintenance.

Applications of Brass Drive Gears

Automotive & Machinery

- Used in speedometers, odometers, and small gear assemblies in vehicles.

- Common in light-duty mechanical systems that require precision.

Watches & Clocks

- Brass gears are essential in clock mechanisms, ensuring smooth and accurate timekeeping.

Household Appliances

- Found in blenders, mixers, coffee machines, and electric fans for smooth and quiet operation.

Industrial Equipment

- Used in textile machinery, printing machines, and automation systems.

- Provides durability in moderate-load applications.

Marine & Water Systems

- Due to their corrosion resistance, brass gears are used in pumps, valves, and ship components.

Musical Instruments

- Found in tuning mechanisms for guitars, violins, and pianos.

Robotics & Precision Instruments

- Ideal for small-scale robotics, sensors, and laboratory equipment where precision is needed.

Comparison: Brass vs. Steel Gears

| Feature | Brass Drive Gear | Steel Drive Gear |

|---|---|---|

| Strength | Moderate | High |

| Corrosion Resistance | Excellent | Prone to rust (unless stainless steel) |

| Wear Resistance | Good | Higher, but requires lubrication |

| Machinability | Easy | Harder to machine |

| Weight | Lighter | Heavier |

| Noise Level | Quiet | Can be noisy |

| Best for | Light to medium loads, precision work | Heavy-duty applications |

Conclusion

Brass drive gears are an excellent choice for applications requiring corrosion resistance, smooth operation, and quiet performance. While they may not be as strong as steel gears, they provide reliable performance in light-to-moderate load systems. Their self-lubricating properties and easy machinability make them a popular choice in automotive, industrial, household, and precision applications.

Shenchi technology co.,is a professional OEM machinery factory located in weneling zhejiang,China. The main business includes CNC turning and milling parts, CNC machining center parts; etc.We can complete the mold product, logo customization and finish services including sandblasting, powder coating, anodizing, electroplating, polishing and laser etching.

©2024. Shenchi Company All Rights Reserved.