- WENLING ZHEJIANG ÇİN

- [email protected]

- 86 18958695512

- Ev

- ÜRÜN

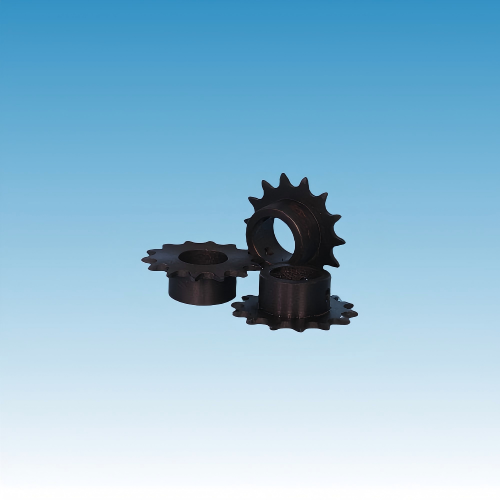

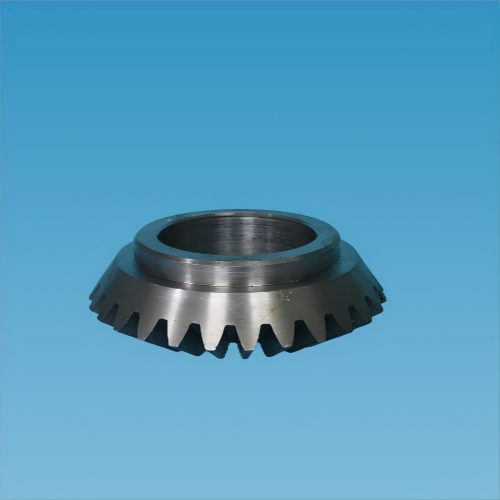

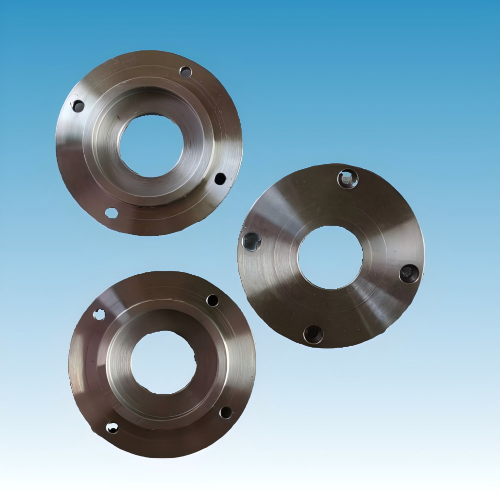

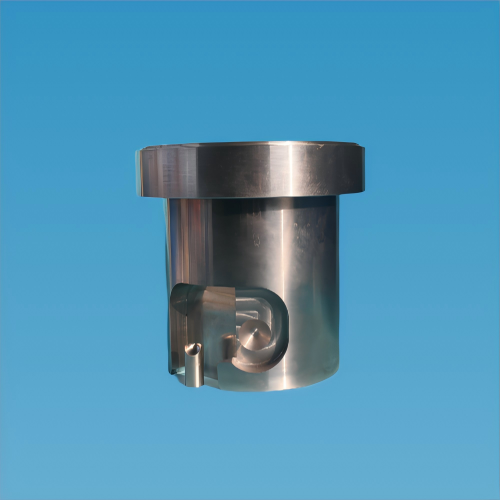

- Tekstil makine parçaları

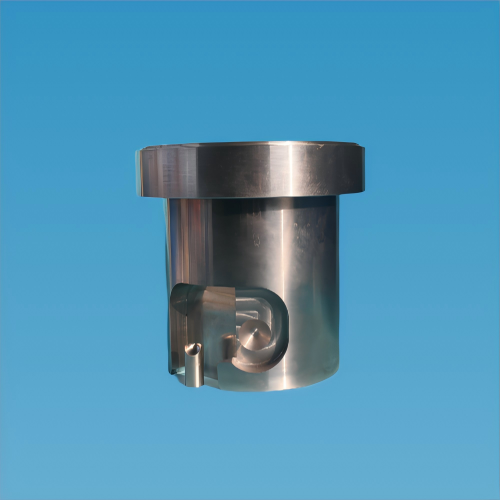

- İpek eğirme makinesi aksesuarları OEM harika makine parçası

İpek eğirme makinası aksesuarları oem dikiş makinası parçaları

İpek eğirme makinası aksesuarları dikiş makinesi parçaları aksesuarları fabrika fiyatı ile oem hassas yedek parça yurtdışına ihracat yapıyor mu

İpek eğirme makinası aksesuarları başvurmak yedek parça ve komponentler kullanılan ipek eğirme makineleriBu aksesuarlar şunları sağlar: düzgün çalışma, verimlilik ve uzun ömür makinede yer alan ipek liflerinin ipliğe veya kumaşa işlenmesi.

ADI:İpek eğirme makinesi aksesuarları

MODEL:SC205FZ2027

MALZEME:ÇELİK

MOQ: İHTİYACINIZ OLDUĞU GİBİ

TESLİMAT: MİKTARINIZA GÖRE

ÖRNEK: SUNULAN ÖRNEK

Menşei Yeri: ZHEJANG ÇİN

HİZMET: OEM ODM ÖZELLEŞTİRİLMİŞ

AVANTAJ: PROFESYONEL EKİP YÜKSEK KALİTE

İpek Eğirme Makineleri için Temel Aksesuarlar

The birincil alıcılar ipek eğirme makinesi aksesuarları şunları içerir: ipek fabrikaları, tekstil fabrikaları, onarım şirketleri, tedarikçiler ve araştırma kurumlarıBu aksesuarlar şunlar için olmazsa olmazdır: verimli ipek işleme, makine performansının korunması ve yüksek kaliteli ipek üretiminin sağlanması.

İplik Bobinleri ve Makaraları – Şunun için kullanılır: ipek ipliklerin sarılması ve depolanması eğirme işlemi sırasında.

Kılavuz Silindirler ve Gergi Cihazları – Uygun şekilde koruyun iplik gerginliği ve ipek liflerinin düzgün hareket etmesini sağlar.

Mil ve Uçanlar – İçin gerekli bükme ve eğirme ipek liflerinin ipliğe dönüştürülmesi.

Çizim Silindirleri ve Taslak Sistemleri – Kontrol edin kalınlık ve düzgünlük ipek iplikten.

Makara Makinesi Parçaları – Bileşenler gibi makaralı tamburlar, kancalar ve ipek sarma cihazları ipek kozasından ipeği çözmek için kullanılır.

Yataklar ve Miller – Makinede dönme hareketlerini destekler düzgün çalışma.

Kayışlar ve Kasnaklar – Mekanik bileşenleri çalıştırarak, tutarlı dönüş hızı.

Isıtma ve Buhar Nozulları – Yardım yumuşatma ve işleme ham ipek lifleri.

Kesiciler ve Düzelticiler – Şunun için kullanılır: ipek filamentlerini kesmek ve kirleri temizler.

Elektronik Kontroller ve Sensörler – İzleme ve düzenleme makine hızı, gerginlik ve kalite kontrolü.

İpek İplik Eğirme Makineleri Aksesuarlarının Uygulamaları

İpek Makaralama ve Filament Çıkarımı – Ham ipek kozasını dönüştürmek sürekli ipek filamentler.

İpek İplik Üretimi – İpek liflerinin eğrilmesi yüksek kaliteli iplik.

Dokuma ve Kumaş İşleme – Kullanıldığı yerler tekstil endüstrisi ince ipek kumaşlar üretmek.

Otomatik İpek İşleme Tesisleri – Modern aksesuarlar yardımcı olur otomasyon ve hassas kontrol.

Verimliliği artırır – Sağlar pürüzsüz ve kesintisiz çalışma İpek eğirme makineleri.

İpek İplik Kalitesini İyileştirir – Uygun aksesuarlar bakıma yardımcı olur iplik tutarlılığı ve dayanıklılığı.

Makine Durma Süresini Azaltır – Yüksek kaliteli parçalar en aza indirilir aşınma ve yıpranma, bakım süresini azaltır.

Maliyet Etkin – Makinelerin ömrünü uzatır, değiştirme maliyetlerini azaltma.

Otomasyonu destekler – Gelişmiş aksesuarlar şunları sağlar: bilgisayarlı kontrol ve hassas işleme.

Çözüm

İpek eğirme makinası aksesuarları hayati bir rol oynamak tekstil ve ipek üretim endüstrisi. Kullanarak dayanıklı ve yüksek hassasiyetli parçalar, üreticiler şunları sağlayabilir: verimli üretim, üstün ipek kalitesi ve azaltılmış bakım maliyetleriDoğru aksesuarlara yatırım yapmak, bakımını yapmak için önemlidir. verimlilik ve rekabet gücü ipekten

İpek eğirme makinesi aksesuarları gerekli için pürüzsüz üretim, yüksek kaliteli iplik, makine verimliliği ve maliyet etkinliğiGüvenilir aksesuarlara yatırım yapmak duruş süresini önler, makine ömrünü uzatır ve genel üretkenliği iyileştirir, onları bir ipek tekstil endüstrisinin önemli bir bileşeni.

Shenchi teknoloji şirketi profesyonel bir şirkettir OEM makine fabrikası Wenling Zhejiang, Çin'de yer almaktadır. Ana faaliyet alanı CNC torna ve freze parçaları, CNC işleme merkezi parçaları vb.'dir. Kumlama, toz kaplama, eloksal, elektrokaplama, parlatma ve lazer kazıma dahil olmak üzere kalıp ürünü, logo özelleştirme ve sonlandırma hizmetlerini tamamlayabiliriz.

© Shenchi Şirketi Tüm Hakları Saklıdır.