- வென்லிங் ஜெஜியாங் சீனா

- [email protected]

- 86 18958695512

- முகப்புப் பக்கம்

- தயாரிப்பு

- பிற தயாரிப்பு கூறுகள்

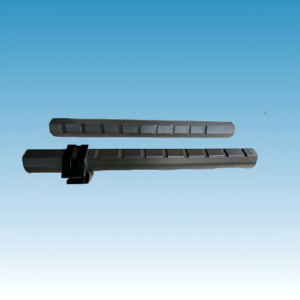

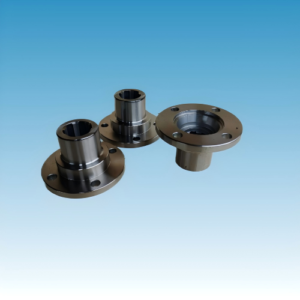

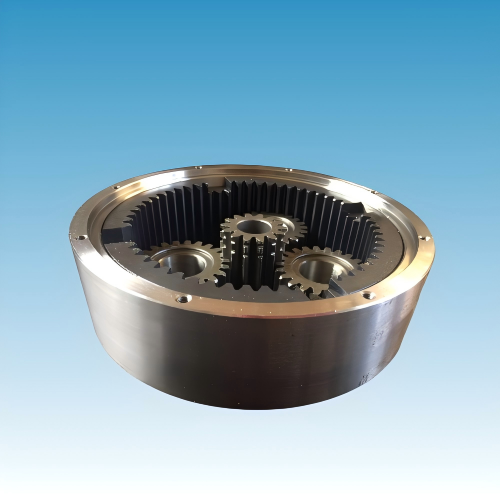

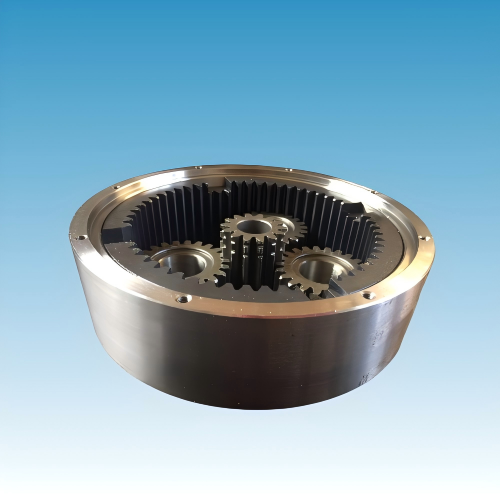

- Reducer parts custom combined transmission gear drive part

Reducer parts custom combined transmission gear drive part

குறைப்பான் பாகங்கள் are the backbone of power transmission systems, ensuring smooth torque conversion, speed adjustment, and mechanical efficiency in countless industrial applications. From heavy mining equipment to precision automation systems, high-quality reducer components directly impact performance, longevity, and operational safety. Here’s why they matter:

1. Core Function: Power Transmission & Torque Control

2. Durability Under Extreme Conditions

3. Efficiency & Energy Savings

4. Customization for Specific Need

5. Safety & Compliance

6. Cost-Effectiveness Over Time

NAME: Reducer parts

MODEL:SC205SC2222

பொருள்: உங்கள் தேவையைப் பின்பற்றுங்கள்

MOQ: உங்கள் தேவைக்கேற்ப

டெலிவரி: உங்கள் அளவின்படி

மாதிரி: மாதிரி வழங்கப்படுகிறது

பிறப்பிடம்: ஜெஜாங் சீனா

சேவை: OEM ODM தனிப்பயனாக்கப்பட்டது

நன்மை: தொழில்முறை குழு உயர் தரம்

Premium Custom Reducer Parts: High-Quality Gear Solutions for Global Buyers

In the world of industrial machinery, reducer gears play a critical role in ensuring smooth power transmission and operational efficiency. As a leading reducer gear manufacturer, we specialize in producing customed reducer parts, including precision gear shafts, to meet the diverse needs of industries such as mining, construction, agriculture, and automation. Our commitment to professional customization, competitive pricing, and superior durability makes us the ideal partner for global buyers seeking reliable reducer components.

Why Choose Our Custom Gear Reducer Parts?

1. Precision Engineering for Optimal Performance

Our gear reducer components are manufactured using advanced CNC machining and grinding technologies, ensuring:

✔ டெல் டெல் ✔ Tight tolerances (up to ±0.005mm) for seamless integration.

✔ டெல் டெல் ✔ High load-bearing capacity with hardened steel (20CrMnTi, 42CrMo).

✔ டெல் டெல் ✔ Custom tooth profiles (spur, helical, bevel) to match your reducer specifications.

2. Cost-Effective Without Compromising Quality

We bridge the gap between affordability and excellence:

Direct factory pricing – 20-30% lower than competitors.

Bulk order discounts – Ideal for large-scale projects.

Long service life – Precision heat treatment extends durability.

3. Tailored Solutions for Every Application

We offer professional customization for:

-

Industrial gear reducers (torque: 50–10,000 Nm)

-

Planetary/cycloidal drives

-

Heavy-duty mining & construction equipment

Our Manufacturing Capabilities

In-house R&D – CAD/CAM-designed gear systems.

Quality Assurance – 100% testing (ISO 9001, AGMA standards).

Fast lead times – 15–30 days for custom orders.

Industries We Serve

-

Mining & Cement – High-torque gear shafts for crushers.

-

Renewable Energy – Precision parts for wind turbine reducers.

-

Food Processing – Stainless steel options for hygiene.

Transmission Gear Factory is a specialized manufacturing facility that produces gears and related components used in various transmission systems. These gears are essential for transferring power and motion in machinery, automotive vehicles, industrial equipment, and other mechanical systems.

Key Functions of a Transmission Gear Factory:

-

Gear Manufacturing – Producing different types of gears (spur, helical, bevel, worm, planetary, etc.) for transmissions.

-

துல்லிய எந்திரம் – Using advanced CNC machines, hobbing, grinding, and shaping to ensure high accuracy.

-

வெப்ப சிகிச்சை – Applying processes like carburizing, quenching, and tempering to enhance durability.

-

Quality Control – Conducting inspections (CMM, gear testing, hardness testing) to meet industry standards.

-

Assembly & Testing – Integrating gears into transmission systems and performing performance tests.

Industries Served:

-

தானியங்கி (cars, trucks, motorcycles)

-

தொழில்துறை இயந்திரங்கள் (conveyors, pumps, compressors)

-

விண்வெளி & பாதுகாப்பு (helicopters, aircraft systems)

-

Renewable Energy (wind turbine gearboxes)

-

Marine & Rail (ship propulsion, train transmissions)

Advanced Technologies Used:

-

CNC Gear Cutting & Grinding

-

5-Axis Machining

-

Laser Measurement & 3D Scanning

-

Automated Production Lines

Why Choose a Professional Gear Factory?

✔ High precision & tight tolerances

✔ Custom gear design & engineering support

✔ High-volume production capability

✔ Compliance with ISO, AGMA, DIN standards

Would you like details on a specific type of gear manufacturing process or industry application

ஷெஞ்சி தொழில்நுட்ப நிறுவனம், ஒரு தொழில்முறை நிறுவனம். OEM இயந்திர தொழிற்சாலை சீனாவின் வென்லிங் ஜெஜியாங்கில் அமைந்துள்ளது. முக்கிய வணிகத்தில் CNC டர்னிங் மற்றும் மில்லிங் பாகங்கள், CNC எந்திர மைய பாகங்கள் போன்றவை அடங்கும். நாங்கள் அச்சு தயாரிப்பு, லோகோ தனிப்பயனாக்கம் மற்றும் மணல் வெட்டுதல், தூள் பூச்சு, அனோடைசிங், எலக்ட்ரோபிளேட்டிங், பாலிஷ் மற்றும் லேசர் எட்சிங் உள்ளிட்ட பூச்சு சேவைகளை முடிக்க முடியும்.

இப்போது குழுசேர்

எங்கள் எதிர்கால புதுப்பிப்புகளைத் தவறவிடாதீர்கள்! இன்றே குழுசேரவும்!

© ஷெஞ்சி நிறுவனம் அனைத்து உரிமைகளும் பாதுகாக்கப்பட்டவை.