- WENLING ZHEJIANG KINA

- [email protected]

- 86 18958695512

- Hem

- PRODUKT

- Andra produkter komponenter

- Sidor

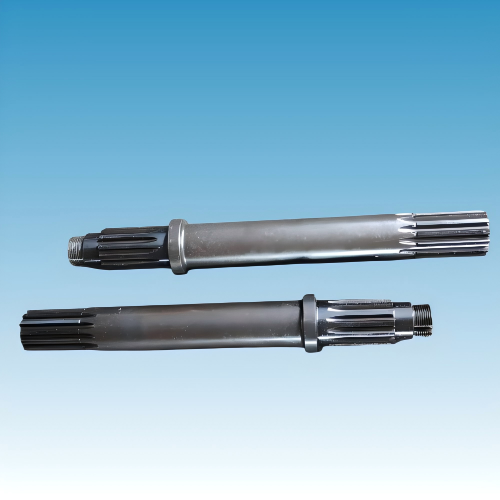

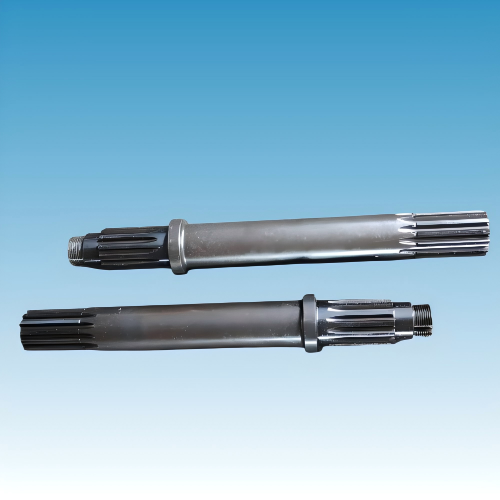

- High Quality Input Shaft Spline Input Shaft OEM drive Shaft

High Quality Input Shaft Spline Input Shaft OEM drive Shaft

Leading shaft-producing nations like Germany, Japan, and China have developed concentrated expertise in precisionsaxel manufacturing through decades of industrial refinement. These regions offer:

Advanced metallurgical knowledge for optimal material selection

Proprietary heat treatment processes enhancing durability

Precision machining capabilities achieving micron-level tolerances

Innovative surface treatment technologies reducing wear

By importing from these specialized manufacturers, businesses gain access to this accumulated technical knowledge that would be prohibitively expensive to develop independently.

NAME: input shaft

MODEL:SC205KJ4122

MATERIAL: FÖLJ DINA KRAV

MOQ: SOM DITT KRAV

LEVERANS: ENLIGT DIN KVANTITET

EXEMPEL: EXEMPEL ERbjuds

URSPRUNGSPLATSEN: ZHEJANG KINA

SERVICE: OEM ODM ANPASSAD

FÖRDEL: PROFESSIONELLT TEAM HÖG KVALITET

High-Quality Shaft Solutions for Your Machinery Needs

In the world of machinery and automotive systems, the axel is a critical component that ensures smooth power transmission and operational efficiency. As a leading manufacturer of high-precision drive shafts, input shafts, and custom shaft machinery, we specialize in producing durable and reliable bildelar that meet the highest industry standards. Our expertise in shaft manufacturing allows us to deliver components that enhance performance, reduce downtime, and extend the lifespan of your equipment.

Whether you are in the automotive, industrial, or heavy machinery sector, our shaft solutions are designed to meet your exact specifications. We utilize advanced machining techniques, high-grade materials, and rigorous quality control to ensure every axel we produce delivers unmatched precision and durability.

Why Choose Our Shaft Products?

1. Superior Material Selection

The foundation of a high-performance axel lies in the quality of materials used. We source premium-grade steel, alloy, and other metals to manufacture drive shafts, input shafts, and other shaft machinery components. Our materials are selected based on strength, wear resistance, and fatigue tolerance, ensuring long-lasting performance even under extreme conditions.

2. Precision Machining & Customization

Every axel we produce undergoes precision machining to meet exact tolerances. Our state-of-the-art CNC machines and grinding equipment allow us to manufacture input shafts, drive shafts, and custom shaft machinery with micron-level accuracy. Whether you need standard or custom-designed bildelar, we can tailor our solutions to fit your unique requirements.

3. Rigorous Quality Control

Quality is at the core of our manufacturing process. Each axel is subjected to stringent testing, including hardness testing, dimensional inspection, and dynamic balancing, to ensure flawless performance. Our commitment to quality guarantees that every component leaving our facility meets or exceeds international standards.

4. Competitive Pricing & Fast Delivery

As a trusted shaft manufacturer, we understand the importance of cost-efficiency and timely delivery. Our streamlined production process and large-scale manufacturing capabilities allow us to offer competitive pricing without compromising quality. Additionally, we maintain an efficient logistics network to ensure fast and reliable delivery to global customers.

Our Shaft Product Range

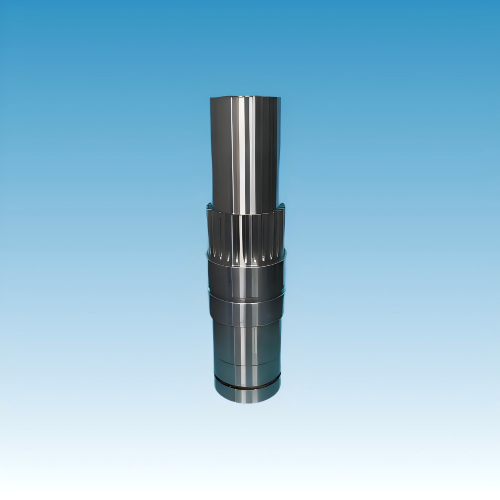

1. Input Shafts

De input shaft is a crucial component in transmissions and drivetrains, responsible for transferring power from the engine to the gearbox. Our input shafts are engineered for optimal strength and smooth operation, making them ideal for automotive, agricultural, and industrial applications.

2. Drive Shafts

A drivaxel plays a vital role in transmitting torque and rotation in vehicles and machinery. Our drivaxlar are designed to withstand high stress and rotational forces, ensuring reliable performance in cars, trucks, and heavy equipment.

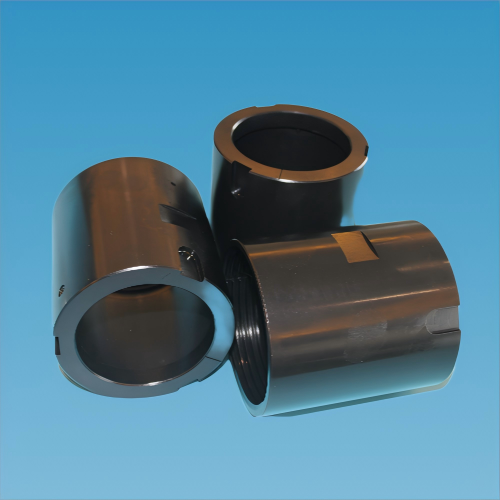

3. Custom Shaft Machinery

Beyond standard bildelar, we specialize in producing custom shaft machinery for specialized applications. Whether you need splined shafts, hollow shafts, or high-speed rotating shafts, our engineering team can develop a solution tailored to your needs.

4. Industrial & Heavy-Duty Shafts

For industries such as mining, construction, and marine, we manufacture heavy-duty shafts capable of handling extreme loads and harsh environments. Our industrial-grade shaft machinery is built to last, reducing maintenance costs and improving operational efficiency.

Applications of Our Shaft Products

Our shafts are widely used across multiple industries, including:

Automotive: Transmissions, differential systems, steering columns

Lantbruk: Tractors, harvesters, and other farming machinery

Industrial Machinery: Pumps, compressors, conveyors, and gearboxes

Construction & Mining: Excavators, cranes, and drilling equipment

Marine & Aerospace: Propulsion systems and high-performance engines

Partner with a Trusted Shaft Manufacturer

When you need high-quality shafts, drive shafts, or input shafts, choosing the right manufacturer is crucial. Our factory combines advanced technology, skilled craftsmanship, and a customer-focused approach to deliver bildelar that exceed expectations.

We invite you to explore our product range and contact us for customized solutions. Let us be your reliable partner for all your shaft machinery needs.

Contact us today to discuss your requirements and request a quote!

Shenchi Technology co., är en professionell OEM maskinfabrik beläget i Wenling Zhejiang, Kina. Huvudverksamheten inkluderar CNC-svarvning och fräsning av delar, CNC-bearbetningscenterdelar, etc. Vi kan komplettera formprodukten, logotypanpassning och finishtjänster inklusive sandblästring, pulverlackering, anodisering, galvanisering, polering och laseretsning.

© Shenchi Company Alla rättigheter reserverade.