- WENLING ZHEJIANG CHINA

- [email protected]

- 86 18958695512

- Lar

- PRODUTO

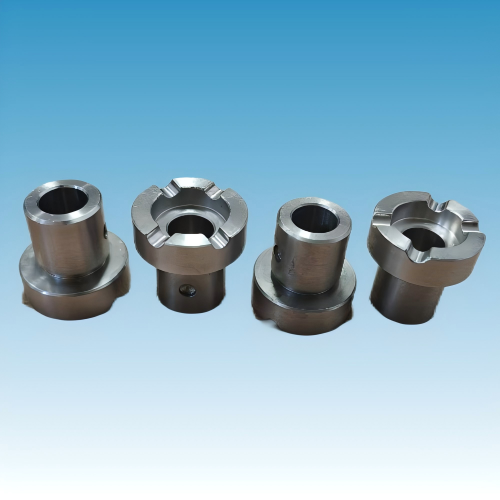

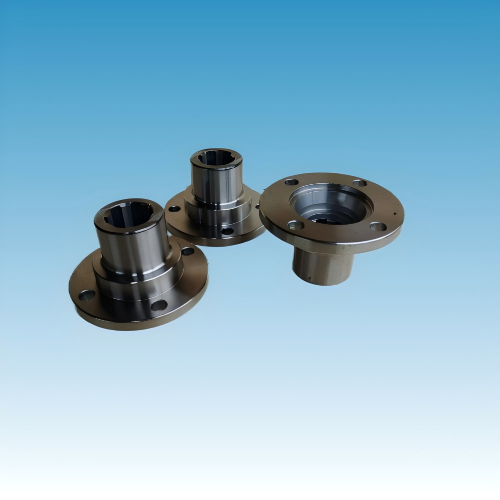

- Outros componentes do produto

- Gearbox shell aluminum Transmission Clutch Housing Gearbox

Gearbox shell aluminum transmission clutch housing gearbox

High-performance Transmission Part Clutch Gearbox Aluminum Shell Transmission Die Cast Housing Heavy Truck Out Cover Clutch Housing Gearbox Casing factory CHINA Aluminum Custom Auto Transfer Gearbox

SC205BB6002

the shell not only meets performance expectations but also adheres to environmental regulations and manufacturing sustainability. Some shells are even designed for easy recycling, contributing to the circular economy in the automotive industry.

NAME:custom auto shell of gearbox

MODEL:SC205BB6002

MATERIAL: SIGA SUA NECESSIDADE

MOQ: CONFORME SUA NECESSIDADE

ENTREGA: DE ACORDO COM SUA QUANTIDADE

AMOSTRA: AMOSTRA OFERECIDA

LOCAL DE ORIGEM: ZHEJANG CHINA

SERVIÇO: OEM ODM PERSONALIZADO

VANTAGEM: EQUIPE PROFISSIONAL ALTA QUALIDADE

What Are the Parts of an Automatic Gearbox Shell?

The automatic gearbox shell, often referred to as the transmission case or housing, is a critical component of an automatic transmission system. It serves as the outer structural framework that houses and supports the various internal components of the gearbox. While the shell itself does not directly transmit power, its role is indispensable in maintaining alignment, reducing vibration, and ensuring the longevity of the transmission system.

Understanding the parts of an automatic gearbox shell involves examining the specific elements integrated into or associated with the shell. Below is a detailed breakdown of the key components and their respective functions.

1. Main Housing (Transmission Case)

The main housing is the core structure of the gearbox shell. It is typically made of high-strength aluminum or cast iron to ensure durability while keeping the weight manageable. Its primary role is to contain the internal components such as gears, shafts, and hydraulic circuits. It also provides structural rigidity and resists deformation under mechanical stress and heat.

2. Bell Housing

The bell housing is an extension of the gearbox shell that connects the transmission to the engine. It encloses the torque converter or clutch assembly and aligns the input shaft with the engine’s crankshaft. In most automatic transmissions, the bell housing is either integrated into the main housing or bolted to it.

3. Mounting Points and Brackets

Mounting points are engineered into the gearbox shell to secure it to the vehicle’s chassis or subframe. These brackets are precision-machined to absorb engine vibrations and torque without transmitting undue stress to the housing or internal components.

4. Cooling Channels and Oil Passages

An automatic transmission generates significant heat during operation. To manage this heat, the gearbox shell includes integrated cooling channels and oil passages. These channels allow transmission fluid to circulate efficiently, cooling internal parts and reducing wear.

5. Inspection and Access Ports

The gearbox shell often contains several access ports for service and inspection. These may include drain plugs, fill plugs, and inspection covers. Some housings also feature ports for installing sensors or connecting diagnostic equipment.

6. Mounting Bosses for Valve Body

The valve body, which controls hydraulic circuits and gear shifting, is mounted inside the shell. The gearbox housing includes precisely positioned bosses and threaded holes to secure the valve body in place. Any misalignment could lead to hydraulic inefficiencies or gear shift problems.

7. Support for Planetary Gear Sets

Automatic transmissions use planetary gear systems to achieve various gear ratios. The shell includes internal ridges, grooves, or mounts that secure and align the planetary gears. Proper support ensures smooth power flow and extends the life of the transmission.

8. Torque Converter Housing (If Separate)

In some designs, the torque converter housing is a distinct part attached to the main case. It encloses the torque converter, which transmits power from the engine to the transmission input shaft. This part must be precisely aligned and securely bolted to avoid vibrations or mechanical failure.

9. Sensor Ports and Mounts

Modern automatic gearboxes rely on various sensors to monitor temperature, speed, pressure, and position. The shell contains provisions for mounting these sensors, including threaded ports and sealed openings that maintain fluid integrity.

10. Sealing Surfaces and Gasket Channels

To prevent fluid leaks, the shell features machined sealing surfaces where it joins with other transmission components like the oil pan or valve body. These surfaces typically include grooves or flanges to accommodate gaskets and O-rings.

11. Reinforcement Ribs

Many gearbox shells include reinforcement ribs molded or cast into the exterior. These structural elements enhance the rigidity of the housing and help distribute stress more evenly across the surface, especially in high-torque applications.

12. Internal Bushing and Bearing Supports

The shell must support several rotating shafts and gears, which requires internal recesses or mounts for bushings and bearings. These components ensure the smooth rotation and alignment of critical transmission parts.

Conclusão

The automatic gearbox shell is far more than a simple casing. It plays a vital role in aligning and protecting internal transmission components, managing thermal stress, and supporting sensors and control modules. Understanding its structure and the integral parts associated with it can provide insight into the engineering complexity behind modern automatic transmissions. When sourcing or manufacturing gearbox shells, attention to material quality, dimensional accuracy, and compatibility with internal components is essential for optimal performance and durability.

An automatic gearbox, also known as an automatic transmission, is a complex mechanical system responsible for shifting gears without the driver’s manual input. It enables the vehicle to change speed and torque smoothly, optimizing engine performance and fuel efficiency. The automatic transmission system has evolved significantly over the years, incorporating both hydraulic and electronic technologies to improve responsiveness, durability, and control. Below are the primary components that make up an automatic gearbox and their functions.

1. Torque Converter The torque converter is a key component that replaces the clutch found in manual transmissions. It connects the engine to the transmission and transfers engine power using fluid dynamics. A torque converter consists of three major elements:

Pump (Impeller): Attached to the engine, it spins and moves transmission fluid.

Turbina: Connected to the transmission input shaft; receives fluid from the pump and causes the vehicle to move.

Stator: Redirects fluid returning from the turbine to the pump, increasing efficiency. The torque converter allows for smooth vehicle starts and efficient power transfer.

2. Planetary Gear Set At the core of every automatic transmission lies the planetary gear set. This gear system enables multiple gear ratios in a compact space. It consists of:

Sun Gear: Center gear.

Planet Gears: Surround and rotate around the sun gear.

Planet Carrier: Holds the planet gears.

Ring Gear: Encircles the planet gears. By locking different parts of the gear set, the transmission can produce various forward and reverse gear ratios.

3. Hydraulic System The hydraulic system controls the transmission’s operation through the use of pressurized transmission fluid. It channels this fluid to activate clutches and bands that engage specific gears. The system includes:

Oil pump: Supplies pressurized fluid.

Valves and solenoids: Control fluid flow to different parts of the gearbox. This system is essential for smooth shifting and effective operation of the gearbox.

4. Clutches and Bands Clutches and bands are responsible for engaging and disengaging the different gears within the transmission.

Embreagens: Packaged in drums, they connect and disconnect rotating shafts.

Bands: Steel straps with friction material that wrap around rotating drums to hold them stationary. When activated hydraulically, they determine which gear is selected by locking parts of the planetary gear set.

5. Valve Body The valve body is often described as the “brain” of the automatic transmission. It is a maze-like control center made up of channels, valves, and solenoids.

Directs hydraulic fluid to the correct clutch pack or band.

Controls shifting according to vehicle speed, engine load, throttle position, and other parameters. Modern valve bodies are electronically controlled by the transmission control module (TCM).

6. Transmission Control Module (TCM) The TCM is an electronic brain that oversees gear shifting in modern vehicles. It collects data from various sensors, such as vehicle speed, engine RPM, throttle position, and more. It uses this data to:

Determine optimal shift points.

Adjust hydraulic pressure.

Monitor and diagnose transmission performance.

7. Output Shaft The output shaft is the final stage of the transmission. It transfers the rotational force (torque) generated through the gear system to the drive shaft, and ultimately to the vehicle’s wheels.

8. Oil Pump and Transmission Fluid The oil pump is crucial for circulating transmission fluid throughout the system. Transmission fluid serves several purposes:

Lubrication

Hydraulic pressure generation

Cooling of moving parts

Cleaning internal components Maintaining proper fluid levels is essential for transmission health.

9. Speed Sensors Modern automatic transmissions rely on input and output speed sensors to provide real-time data to the TCM. These sensors help determine:

Shift timing

Engine load

Gear position

Conclusão An automatic gearbox is a marvel of mechanical and electronic engineering, built from numerous interdependent components. Each part plays a crucial role in enabling seamless gear shifts and efficient power delivery. Understanding these components can help with diagnostics, maintenance, and making informed decisions about vehicle care or transmission upgrades. Whether you’re an enthusiast, mechanic, or curious car owner, knowing the parts of an automatic transmission enhances your appreciation of modern automotive technology.

Shenchi technology co., é uma empresa profissional Fábrica de máquinas OEM localizado em Wenling zhejiang, China. O negócio principal inclui peças de torneamento e fresamento CNC, peças de centro de usinagem CNC, etc. Podemos concluir o produto do molde, personalização de logotipo e serviços de acabamento, incluindo jateamento de areia, revestimento em pó, anodização, galvanoplastia, polimento e gravação a laser.

© Shenchi Company Todos os direitos reservados.