- ਵੈਨਲਿੰਗ ਝੇਜਿਆਂਗ ਚੀਨ

- [email protected]

- 86 18958695512

- ਮੁੱਖ ਪੇਜ

- ਉਤਪਾਦ

- ਹੋਰ ਉਤਪਾਦਾਂ ਦੇ ਹਿੱਸੇ

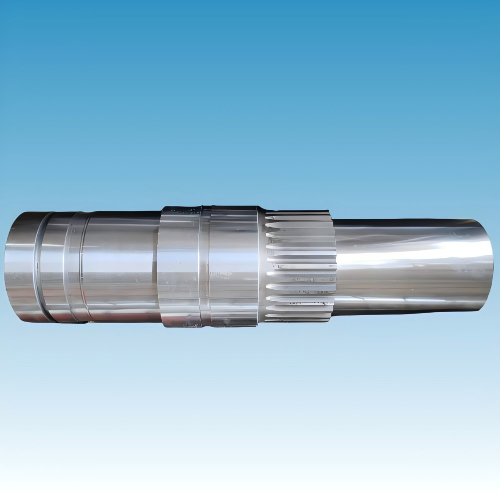

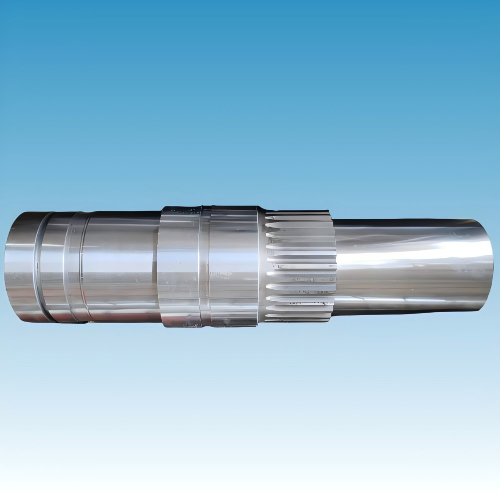

- Mining Machine Spindle high quality Main heavy Shaft roller

Mining Machine Spindle Main Shaft roller in Mining Equipment

As a leading manufacturer of Mining Machine Spindle ਅਤੇ Main Shaft Rollers, we specialize in producing heavy-duty components that ensure reliability in the most demanding mining operations. Our Main Shaft Rollers are engineered to deliver exceptional durability, precision, and cost efficiency for large mining machines such as crushers, ball mills, and drilling rigs.

Why Choose Our Main Shaft Rollers?

Superior Material Quality

ਸ਼ੁੱਧਤਾ ਮਸ਼ੀਨਿੰਗ

Custom Solutions

Extended Service Life

NAME: Mining Machine Spindle

MODEL:SC205KJ4122

ਸਮੱਗਰੀ: ਆਪਣੀ ਜ਼ਰੂਰਤ ਦੀ ਪਾਲਣਾ ਕਰੋ

MOQ: ਤੁਹਾਡੀ ਲੋੜ ਅਨੁਸਾਰ

ਡਿਲੀਵਰੀ: ਤੁਹਾਡੀ ਮਾਤਰਾ ਦੇ ਅਨੁਸਾਰ

ਨਮੂਨਾ: ਪੇਸ਼ ਕੀਤਾ ਗਿਆ ਨਮੂਨਾ

ਮੂਲ ਸਥਾਨ: ਜ਼ੇਜਾਂਗ ਚੀਨ

ਸੇਵਾ: OEM ODM ਅਨੁਕੂਲਿਤ

ਫਾਇਦਾ: ਪੇਸ਼ੇਵਰ ਟੀਮ ਉੱਚ ਗੁਣਵੱਤਾ

Premium Main Shaft Rollers & Mining machine spindle for mining equipment– Durable, Custom, and Cost-Effective Solutions

In the demanding world of mining operations, equipment reliability is non-negotiable. As a leading manufacturer of Mining Machine Spindle ਅਤੇ Main Shaft Rollers for Mining Equipment, we specialize in producing high-performance, long-lasting components that keep large mining machines running efficiently under extreme conditions.

Our factory combines precision engineering, advanced materials, and competitive pricing to deliver customized shaft rollers that meet the toughest industry standards. Whether you need replacements for crushers, ball mills, or drilling rigs, we provide durable, cost-effective solutions tailored to your machinery.

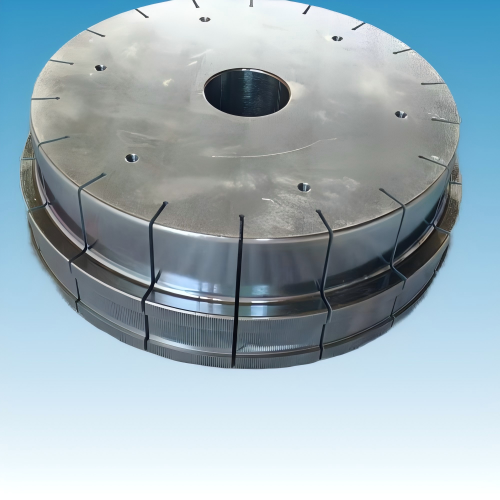

1. The Critical Role of Main Shaft Rollers in Mining Equipment

Main Shaft Rollers are essential components in:

Crushers & Grinding Mills – Transmit power and withstand heavy loads.

Drilling Rigs – Support rotational force in deep excavation.

Conveyor Systems – Ensure smooth material transport.

Why Quality Matters:

High load-bearing capacity (up to 100+ tons).

Resistance to abrasion & impact – Extends component lifespan.

Precision alignment – Reduces vibration and premature wear.

Failure Risks with Low-Quality Rollers:

Increased downtime – Frequent replacements disrupt production.

Higher maintenance costs – Premature wear damages adjacent parts.

Safety hazards – Sudden failures can cause accidents.

2. Our Factory’s Professional Expertise

With 20+ years of experience, we stand out as a trusted Mining Machine Spindle manufacturer.

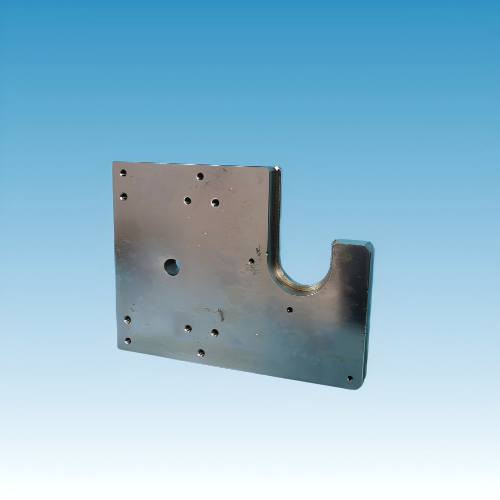

A. Advanced Manufacturing Capabilities

ਸੀਐਨਸੀ ਮਸ਼ੀਨਿੰਗ – Ensures tolerances within ±0.01mm for perfect fitment.

ਗਰਮੀ ਦਾ ਇਲਾਜ – Induction hardening (HRC 58-62) for superior wear resistance.

Dynamic Balancing – Reduces vibration for smoother operation.

B. Rigorous Quality Control

Ultrasonic testing – Detects internal flaws.

Hardness verification – Ensures material durability.

Dimensional inspection – Guarantees precise specifications.

C. Industry Certifications

ISO 9001 – Quality management compliance.

CE & ASTM Certified – Meets global mining equipment standards.

3. Customization for Every Mining Application

We engineer Main Shaft Rollers to match your exact requirements:

A. Material Options

| Material | Best For | Hardness (HRC) |

|---|---|---|

| 42CrMo Alloy Steel | Heavy-duty crushers | 58-62 |

| ਸਟੇਨਲੇਸ ਸਟੀਲ | Corrosive environments | 50-55 |

| Carbide-Coated | Extreme abrasion resistance | 65+ |

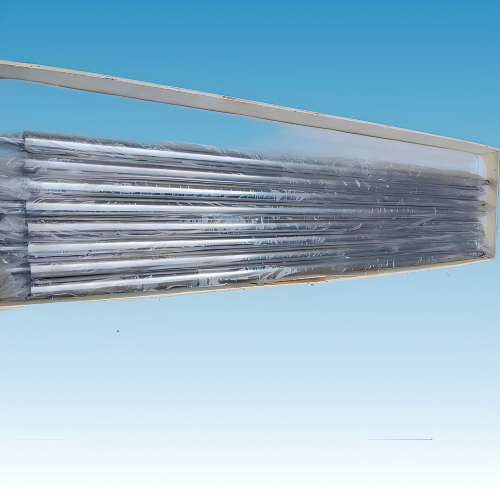

B. Size & Design Flexibility

Diameter: 50mm – 1000mm

Length: Up to 5000mm

Custom keyways, splines, and flange designs

Case Study: A copper mine increased shaft roller lifespan by 40% after switching to our carbide-coated rollers.

4. Unbeatable Price-to-Performance Ratio

We offer high-quality at competitive prices through:

In-house production – No middlemen, lower costs.

Bulk order discounts – Reduced pricing for large quantities.

Fast lead times – 30-45 days for custom orders.

5. Industries & Applications

Our Main Shaft Rollers are used in:

Mineral Processing – Crushers, ball mills, SAG mills.

Coal Mining – Longwall shearers, conveyor drives.

Oil & Gas Drilling – Rotary table shafts.

Why Global Miners Trust Us:

30% longer service life vs. industry average.

24/7 technical support for urgent needs.

6. Easy Ordering Process

Share Specifications – Load capacity, dimensions, material.

Receive Proposal – CAD drawings + quote in 48 hours.

Test Samples – Approve before mass production.

Fast Delivery – Global shipping (EXW/FOB/DDP).

Limited Offer: Free engineering consultation for mining machine spindle

Partner with a Leading Mining Component Manufacturer

We don’t just sell parts—we provide reliable solutions for your toughest mining challenges.

ਸ਼ੇਨਚੀ ਤਕਨਾਲੋਜੀ ਕੰਪਨੀ, ਇੱਕ ਪੇਸ਼ੇਵਰ ਹੈ OEM ਮਸ਼ੀਨਰੀ ਫੈਕਟਰੀ ਵੇਨਲਿੰਗ ਝੇਜਿਆਂਗ, ਚੀਨ ਵਿੱਚ ਸਥਿਤ ਹੈ। ਮੁੱਖ ਕਾਰੋਬਾਰ ਵਿੱਚ ਸੀਐਨਸੀ ਟਰਨਿੰਗ ਅਤੇ ਮਿਲਿੰਗ ਪਾਰਟਸ, ਸੀਐਨਸੀ ਮਸ਼ੀਨਿੰਗ ਸੈਂਟਰ ਪਾਰਟਸ, ਆਦਿ ਸ਼ਾਮਲ ਹਨ। ਅਸੀਂ ਮੋਲਡ ਉਤਪਾਦ, ਲੋਗੋ ਕਸਟਮਾਈਜ਼ੇਸ਼ਨ ਅਤੇ ਫਿਨਿਸ਼ ਸੇਵਾਵਾਂ ਨੂੰ ਪੂਰਾ ਕਰ ਸਕਦੇ ਹਾਂ ਜਿਸ ਵਿੱਚ ਸੈਂਡਬਲਾਸਟਿੰਗ, ਪਾਊਡਰ ਕੋਟਿੰਗ, ਐਨੋਡਾਈਜ਼ਿੰਗ, ਇਲੈਕਟ੍ਰੋਪਲੇਟਿੰਗ, ਪਾਲਿਸ਼ਿੰਗ ਅਤੇ ਲੇਜ਼ਰ ਐਚਿੰਗ ਸ਼ਾਮਲ ਹਨ।

© ਸ਼ੇਨਚੀ ਕੰਪਨੀ ਸਾਰੇ ਹੱਕ ਰਾਖਵੇਂ ਹਨ।