- WENLING ZHEJIANG CHINA

- [email protected]

- 86 18958695512

- Rumah

- PRODUK

- Auto components

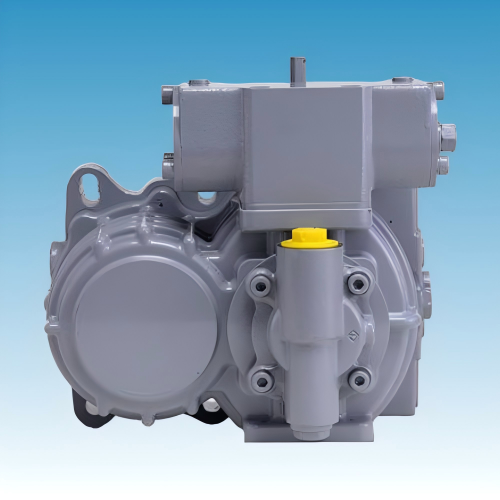

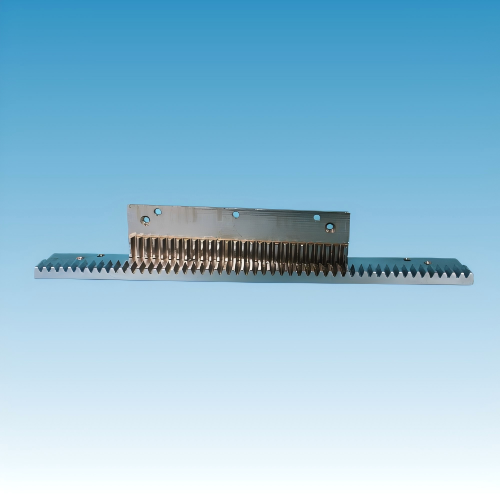

- Ring gear Reduction Gearbox high quality Machiny Gear part

Ring gear Reduction Gearbox high quality Machiny Gear part

When it comes to reliable power transmission and heavy-load applications, ring gears are essential components in various mechanical systems. Designed to deliver high torque and stable performance, it plays a central role in gear reduction systems. As a trusted supplier of mechanical components, we specialize in the manufacturing and export of ring gear spare parts, particularly for reduction gear boxes used in industrial equipment.

The ring gear for reduction gear box is engineered to manage high power loads and ensure smooth speed reduction in rotating systems

NAMA: Ring gear

MODEL:SC205RG4124

BAHAN: IKUT KEPERLUAN ANDA

MOQ: SEBAGAI KEPERLUAN ANDA

PENGHANTARAN: MENGIKUT KUANTITI ANDA

CONTOH: CONTOH DITAWARKAN

TEMPAT ASAL: ZHEJANG CHINA

PERKHIDMATAN: OEM ODM DISESUAIKAN

KELEBIHAN: PASUKAN PROFESIONAL BERKUALITI TINGGI

Premium Ring Gear Spare Parts: Precision Solutions for Reduction Gear Boxes

In the world of industrial machinery and power transmission, ring gears play a pivotal role in ensuring seamless, efficient, and powerful mechanical performance. As one of the most critical components in reduction gear boxes, they are indispensable in a wide range of sectors—from mining and metallurgy to cement, marine propulsion, wind power, and heavy-duty manufacturing.

As a professional supplier of mechanical spare parts, we understand the precision, durability, and reliability that international buyers demand from gear spare parts. In this article, we’ll explore everything you need to know about ring gears, their function in reduction gear boxes, how they are manufactured, and what buyers should consider when sourcing from reliable Chinese suppliers.

What Is a Ring Gear?

It is a large, circular gear with teeth cut into its inner or outer circumference. It serves as a fundamental part of gear reduction systems by transferring torque and rotational motion between mechanical components.

In most applications,they are used in planetary gear systems atau reduction gear boxes, where they interact with pinion gears or planet gears to reduce speed while increasing torque. This makes them especially suitable for high-torque, low-speed applications.

Key Functions of Ring Gears in Reduction Gear Boxes

Reduction gear boxes are designed to convert high-speed input from motors into lower-speed, high-torque output.

Torque Transmission: The ring gear for reduction gear box helps transfer torque between the driving motor and the load with minimal energy loss.

Speed Reduction: The gear ratios provided by ring and pinion interaction reduce rotational speed without sacrificing power.

Load Distribution: In planetary systems, ring gears distribute load evenly across multiple contact points, enhancing durability and service life.

Compact Design: Ring gears enable high power density in compact gear box assemblies, which is ideal for space-constrained industrial setups.

Applications of Ring Gear Spare Parts

they are used in a wide array of industrial and commercial machinery. Typical applications include:

Wind turbines

Mining crushers

Cement rotary kilns

Marine propulsion systems

Steel rolling mills

Conveyor systems

Heavy-duty trucks and off-road equipment

These gears are often subject to harsh working conditions—high torque, heavy loads, and extreme temperatures—which is why high-quality ring gear spare parts are essential for smooth operations and minimal downtime.

Ring Gear Manufacturing Process

Producing high-quality alat ganti gear requires precision engineering, robust materials, and advanced manufacturing processes. Here’s an overview of how our facility ensures top-grade ring gear production:

1. Material Selection

We use high-grade alloy steel such as 42CrMo, 35CrMo, and forged carbon steel. The materials are carefully selected for their strength, wear resistance, and hardenability.

2. Forging & Casting

Depending on the application, ring gears can be:

Forged, for high-strength, heavy-load scenarios

Cast, for more complex shapes or cost-effective solutions

3. Rough Machining

After forging or casting, the gear blank is pre-machined to near-net dimensions using CNC lathes and milling machines.

4. Gear Hobbing or Shaping

Gear teeth are cut with hobbing or shaping machines. For inner ring gears, gear shaping is typically used.

5. Rawatan Haba

Heat treatment processes such as carburizing, quenching, and tempering are applied to improve hardness and wear resistance.

6. Finish Machining

Final dimensional accuracy is achieved through CNC grinding, gear honing, or skiving.

7. Inspection and Testing

Each ring gear for reduction gear box is tested for:

Runout

Tooth profile accuracy (DIN standards)

Surface hardness

Internal defects (ultrasonic and magnetic particle inspection)

We ensure every gear matches strict quality standards before shipment.

Customization Capabilities

One of our core strengths is our ability to customize gear spare parts based on the buyer’s drawing, specifications, or samples. Our engineering team works with clients to define:

Gear module and number of teeth

Pressure angle

Tooth profile: spur, helical, or bevel

Inner or outer ring gear

Hardness and material requirements

Gear face width and outside diameter

Bore type: keyed, spline, or plain

Whether for a new project or replacement parts for aging machinery, we ensure precise fit and long-lasting performance.

Advantages of Our Ring Gear Spare Parts

Ketepatan Tinggi

We use advanced CNC machines and German inspection instruments to ensure tooth profile and pitch diameter within micrometer-level tolerances.

Hayat Perkhidmatan yang Panjang

Through optimized heat treatment and surface finishing, our ring gears offer excellent resistance to wear and fatigue even under heavy-duty cycles.

Fast Turnaround

With stocked raw materials and modular production lines, we can complete and ship custom ring gears in 15–30 days depending on quantity.

Global Export Experience

We have exported ring gears for reduction gear boxes to customers in:

Germany

Italy

South Korea

Brazil

USA

Russia

Our logistics team is familiar with DDU, DDP, FOB, and CIF shipping terms, ensuring smooth cross-border trade.

What Mechanical Parts Buyers Should Consider When Purchasing Gears

Gear Accuracy Level: Ask for DIN or AGMA standards for tooth accuracy and runout tolerance.

Heat Treatment Specs: Check hardness depth (HRC) and surface treatment (nitriding, induction, carburizing).

Material Certs: Request mill test certificates and material origin if required.

Dimensions Tolerances: Ensure your drawings include tolerance zones and gear profiles.

After-Sales Policy: Clarify warranty, replacement terms, and technical support availability.

Supplier Reputation: Choose a ring gear manufacturer with international references, export history, and third-party audit reports.

Conclusion: Your Trusted Supplier for Ring Gear Spare Parts

As a professional mechanical parts manufacturer in China, we are committed to supplying precision-engineered ring gear spare parts for global industries. Whether you need standard designs or custom solutions, our workshop is equipped to deliver products that meet your technical demands and business goals.

From material procurement and gear cutting to inspection and shipping, every step of our production is designed with quality and customer satisfaction in mind.

Jika anda sedang mencari reduction gear box parts that combines strength, accuracy, and long-term performance, we welcome you to send inquiries, drawings, or RFQs. Our sales team will respond within 12 hours with a detailed quotation and technical support.

Shenchi technology co., adalah seorang profesional Kilang jentera OEM terletak di Wenling zhejiang, China. Perniagaan utama termasuk bahagian memusing dan mengisar CNC, bahagian pusat pemesinan CNC, dan lain-lain.Kami boleh melengkapkan produk acuan, penyesuaian logo dan perkhidmatan kemasan termasuk sandblasting, salutan serbuk, anodizing, penyaduran elektrik, penggilap dan etsa laser.

Langgan Sekarang

Jangan terlepas kemas kini masa hadapan kami! Dapatkan Langganan Hari Ini!

© Syarikat Shenchi Hak Cipta Terpelihara.