- WENLING ZHEJIANG CHINA

- [email protected]

- 86 18958695512

- Home

- PRODUCT

- Textile machinery components

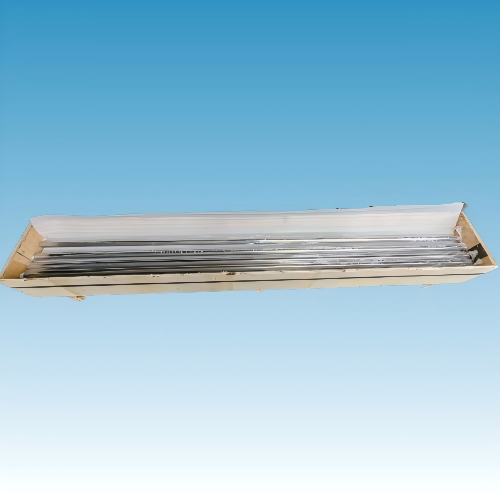

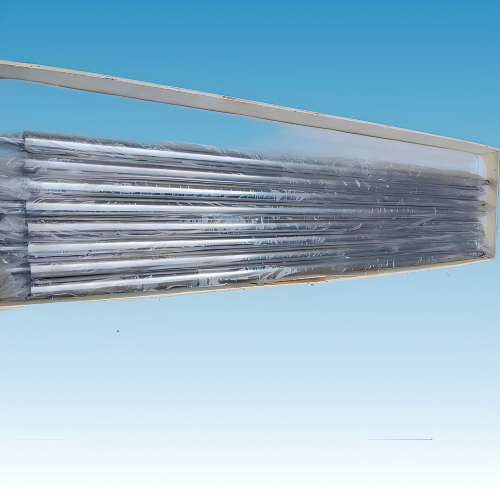

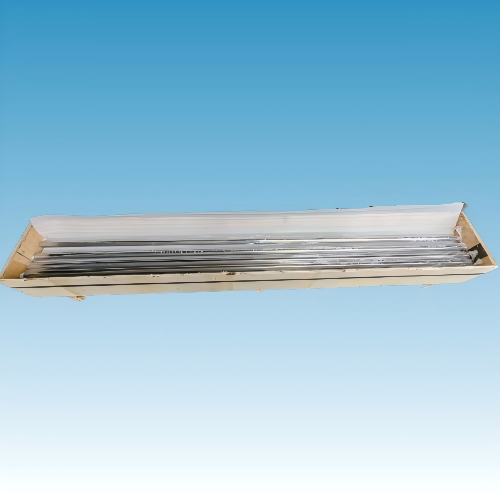

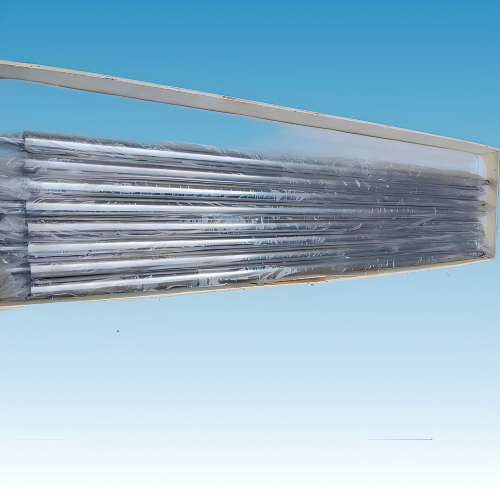

- Linear long shaft high quality custom precision round shaft

Linear long shaft high quality custom precision round shaft

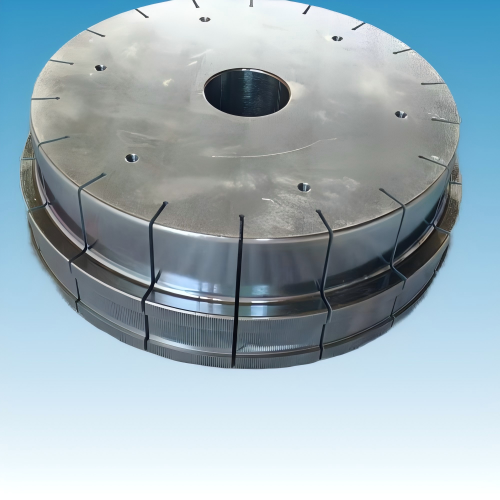

Linear Long Shaft High Quality Customed long Shaft Stainless Steel CNC Machined Precision Shaft Manufacturers Mechanical Products Long Round Solid Drive Shaft

SC205FZ2014

linear long shaft is a precision-machined shaft used in various industrial applications, primarily for motion control, automation, and power transmission. These shafts are crucial components in linear motion systems, supporting the smooth movement of machine parts.

NAME: Linear Long Shaft

MODEL: SC205FZ2014

MATERIAL: FOLLOW YOUR REQUIREMENT

MOQ: AS YOUR REQUIREMENT

DELIVERY: ACCORDING TO YOUR QUANTITY

SAMPLE: SAMPLE OFFERED

ORIGIN PLACE: ZHEJANG CHINA

SERVICE: OEM ODM CUSTOMIZED

ADVANTAGE: PROFESSIONAL TEAM HIGH QUALITY

Why Linear Long Shaft popular

Linear long shafts are popular due to their critical role in precision engineering, automation, and industrial applications. Here are some key reasons why they are widely used:

1. High Precision and Smooth Motion

Linear long shafts provide accurate linear movement, making them essential in CNC machines, robotics, and automation systems. Their precision helps reduce mechanical errors and ensures smooth operation.

2. Durability and Strength

Manufactured from high-quality materials such as stainless steel or carbon steel, these shafts offer excellent strength, wear resistance, and long-lasting performance, even under heavy loads.

3. Versatility in Applications

They are used in diverse industries, including manufacturing, medical devices, automotive, textile machinery, and aerospace. Their ability to support high-speed and repetitive movements makes them essential in various systems.

4. Low Friction and High Efficiency

With proper surface treatment, such as chrome plating or heat treatment, linear long shafts minimize friction, enhancing efficiency and reducing maintenance needs in machinery.

5. Compatibility with Bearings and Guide Rails

These shafts work seamlessly with linear bearings, ball screws, and guide rails, making them integral components in automation and motion control systems.

6. Customizability

Available in various diameters, lengths, and coatings, linear long shafts can be tailored to specific industry requirements, making them adaptable for different machinery and equipment.

7. Cost-Effective Performance

Despite their high-quality construction, linear long shafts provide excellent value by improving machine efficiency, reducing maintenance costs, and extending equipment lifespan.

Due to these advantages, linear long shafts remain a preferred choice for industries that rely on precision motion control, stability, and long-term reliability. Let me know if you need further details!

Industries & Buyers of Linear Long Shafts

1. Industrial Automation & Robotics Companies

Linear long shafts are widely used in CNC machines, automated assembly lines, and robotic arms.

CNC Machine Manufacturers – Use linear shafts for precise movement in milling, lathe, and drilling machines.

Robot & Cobots Manufacturers – Employ linear shafts in actuators and robotic joints.

Automated Packaging & Sorting Companies – Require long shafts for conveyor belt rollers and pick-and-place machines.

2. Automotive & Transportation Industry

The automotive industry purchases linear long shafts for manufacturing lines, testing equipment, and vehicle components.

Automotive Parts Manufacturers – Use linear shafts in production robots, transmission systems, and suspensions.

Electric Vehicle (EV) Manufacturers – Employ high-precision shafts in EV motor assemblies and battery production.

Railway & Aerospace Engineering Firms – Need custom shafts for landing gears, train braking systems, and aircraft actuators.

3. Machine Tool & Equipment Manufacturers

Industrial machinery manufacturers integrate linear motion shafts into various factory and processing equipment.

Textile Machine Manufacturers – Use long shafts in loom frames, weaving machines, and embroidery equipment.

Printing Press & Packaging Machine Producers – Require shafts for paper feeding and roller mechanisms.

Metal Processing Companies – Utilize long shafts for cutting, bending, and forming machines.

4. Construction & Heavy Equipment Manufacturers

Linear shafts are essential in hydraulic systems, lifting equipment, and heavy-duty cranes.

Forklift & Crane Manufacturers – Use linear shafts for lifting arms and stabilizing mechanisms.

Excavator & Road Paving Machine Producers – Integrate shafts into hydraulic piston systems and drilling rigs.

Bridge & Tunnel Construction Companies – Employ custom shafts in foundation drilling and boring machines.

5. Furniture & Home Automation Industry

Modern home and office automation systems require linear shafts for smooth movement.

Adjustable Desk & Chair Manufacturers – Use shafts in height-adjustable office furniture.

Smart Home & Sliding Door Companies – Need long shafts for motorized window blinds and automatic doors.

Medical Bed & Rehabilitation Equipment Suppliers – Use shafts in hospital beds, wheelchairs, and therapy devices.

6. Electronics & Semiconductor Industry

Precision shafts are used in semiconductor fabrication, LCD manufacturing, and 3D printing.

Semiconductor Equipment Manufacturers – Use long shafts for wafer processing and circuit board assembly.

3D Printer Companies – Need smooth shafts for precise printing head movement.

LCD & Display Manufacturers – Utilize shafts in screen printing and cutting machines.

7. Custom Engineering & Fabrication Workshops

Small to mid-sized machine shops and fabrication companies purchase linear long shafts for custom-built machinery and replacement parts.

Prototype Development Firms – Use shafts for specialized machine designs.

Metalworking & Welding Shops – Need custom shafts for structural supports and rotating equipment.

Repair & Maintenance Service Providers – Purchase shafts as replacement parts for industrial machines.

Linear long shafts are vital components in various industries, including manufacturing, automation, automotive, electronics, and construction. Companies purchase them for motion control, precision machining, and industrial automation.

If you need help finding a supplier, manufacturer, or custom design solution for linear long shafts, let me know!

Shenchi technology co.,is a professional OEM machinery factory located in Wenling zhejiang,China. The main business includes CNC turning and milling parts, CNC machining center parts, etc.We can complete the mold product, logo customization and finish services including sandblasting, powder coating, anodizing, electroplating, polishing and laser etching.

© Shenchi Company All Rights Reserved.