- 원링 저장 중국

- [email protected]

- 86 18958695512

- 집

- 제품

- Auto components

- 페이지

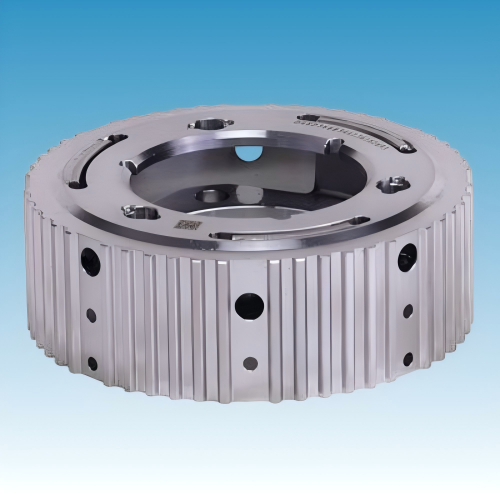

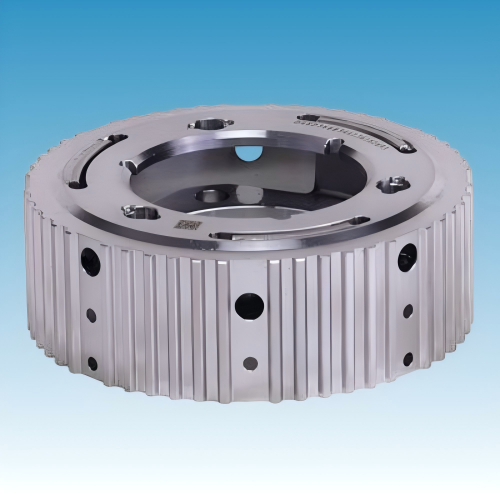

- Front planet carrier assembly useful advance auto parts 3668

Front planet carrier assembly Hot Selling advance auto parts

As a leading manufacturer of high-quality transmission parts, we specialize in producing front planet carrier assemblies, a critical component in modern automotive transmissions. These assemblies are essential for transferring torque and ensuring smooth gear shifts, making them a hot-selling item in the Advance Auto Parts market and other major distribution channels.

With years of expertise in transmission parts, our factory is committed to delivering top-tier planetary gear systems and carrier assemblies. Whether you need bulk orders or customized designs, we provide reliable solutions to meet market demands.

NAME:Front planet carrier assembly

MODEL:SC205JD-AC1002

재료: 귀하의 요구 사항을 따르세요

최소주문수량: 귀하의 요구 사항에 따라

배송: 귀하의 수량에 따라

샘플: 샘플 제공

원산지: 중국 저장성

서비스: OEM ODM 맞춤형

장점: 전문가 팀 고품질

Advance auto parts --Front planet carrier assembly hot selling transmission Parts

In the world of transmission systems, the Front Planet Carrier Assembly is a critical component that ensures smooth power transfer in automotive and heavy machinery applications. As a leading manufacturer of mechanical transmission parts, we specialize in producing high-precision, durable, and custom-engineered planet carrier assemblies tailored to meet the exact specifications of global buyers.

Whether you are an OEM manufacturer, distributor, or aftermarket supplier, our factory delivers high-performance planet carriers with strict tolerances, superior material strength, and reliable durability—all at competitive pricing.

Why Buyers Choose Our Front Planet Carrier Assembly?

1. Custom Manufacturing Based on Your Drawings

We accept 2D/3D drawings (DWG, STEP, IGES, PDF) and produce according to your exact requirements.

Our engineering team provides DFM (Design for Manufacturing) feedback to optimize cost and performance.

Capable of handling prototyping, small-batch, and mass production with flexible MOQs.

2. High-Strength Materials & Heat Treatment

Material Options: 20CrMnTi, 42CrMo, SCM440, or custom alloys for enhanced durability.

Heat Treatment: Carburizing, quenching, tempering, and induction hardening to achieve HRC 58-62 hardness for wear resistance.

Shot peening & stress relief to prevent deformation under high torque.

3. Advanced CNC Machining & Gear Processing

5-Axis CNC Milling & Turning (±0.01mm precision) for complex geometries.

Broaching & Spline Machining for precise internal/external gear teeth.

Gear Grinding & Honing to ensure smooth meshing with planetary gears.

4. Rigorous Quality Control for Zero Defects

100% Dimensional Inspection (CMM & Optical Measuring Machines).

Hardness Testing & Metallographic Analysis for material consistency.

Dynamic Balancing Test (ISO 1940-1 Standard) to minimize vibration.

Salt Spray Test & Anti-Corrosion Coating for long-term reliability.

5. Fast Turnaround & Global Logistics Support

15-20 Days for Prototypes, 30-35 Days for Mass Production.

Export Experience: Smooth shipments to Europe, North America, Russia, and Southeast Asia.

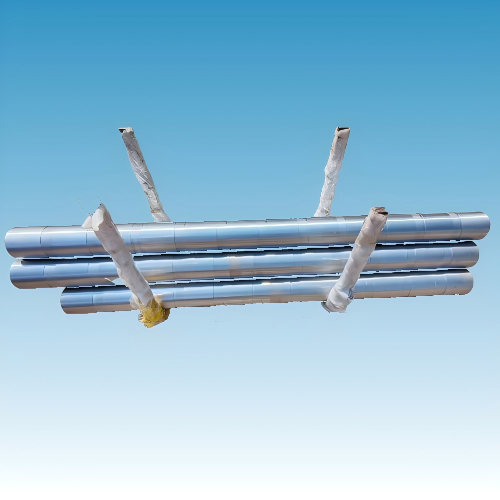

Packaging: Wooden cases + anti-rust oil/VCI film for safe transportation.

Who Needs Our Front Planet Carrier Assembly?

Our transmission parts are widely used in:

Automotive Transmissions (Cars, Trucks, SUVs)

중장비 (Construction, Agricultural, Mining Equipment)

Motorcycle & ATV Drivetrains

Industrial Gearboxes & Power Transmission Systems

Case Study: Successful Supply to European Automotive Supplier

Client: A leading transmission parts distributor in Germany

Challenge: Needed a high-wear-resistant planet carrier with strict DIN standards and a fast delivery timeline.

Our Solution:

Supplied 1,000 pcs/month of 42CrMo heat-treated carriers

Achieved Ra 0.8μm surface finish for reduced friction

Reduced client’s procurement cost by 20% compared to local suppliers

Result: The client has been ordering monthly bulk shipments for 2+ years.

Why Choose Us as Your Planet Carrier Supplier?

20+ Years in Precision Machining – ISO 9001 & IATF 16949 Certified

End-to-End Service – From raw material to finished assembly

Competitive Pricing – No middlemen, direct factory quotes

24/7 Technical Support – Quick response to RFQs & engineering changes

Get Your Custom Front Planet Carrier Quote Today!

Let’s discuss how we can meet your transmission parts needs with high-quality, cost-effective machining solutions!

Shenchi technology co.는 전문가입니다 OEM 기계 공장 중국 저장성 웬링에 위치합니다. 주요 사업은 CNC 터닝 및 밀링 부품, CNC 머시닝 센터 부품 등입니다. 우리는 모래 분사, 분말 코팅, 양극 산화, 전기 도금, 연마 및 레이저 에칭을 포함한 금형 제품, 로고 사용자 정의 및 마무리 서비스를 완료할 수 있습니다.

© Shenchi Company 모든 권리 보유.