- 温嶺 浙江省 中国

- お問い合わせ

- 86 18958695512

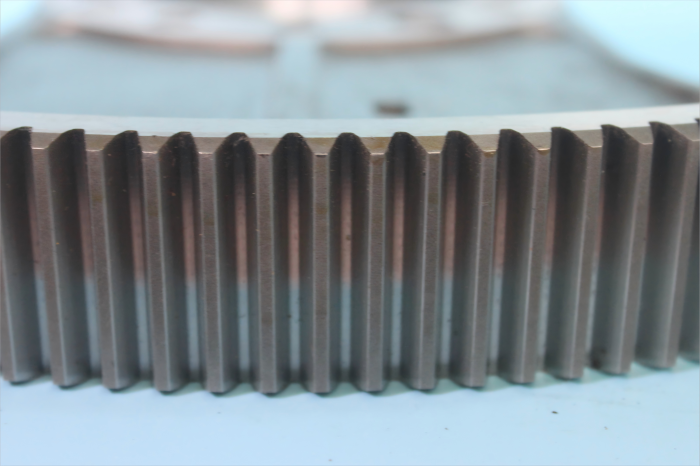

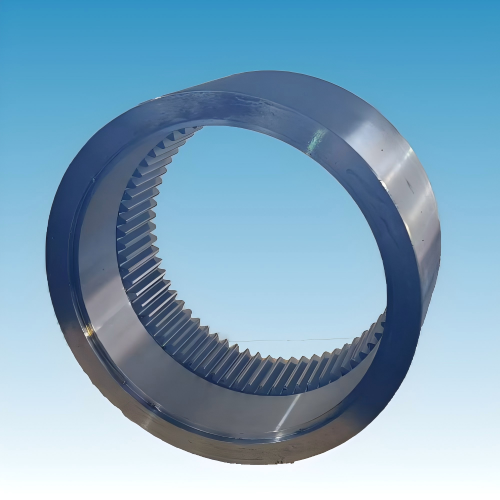

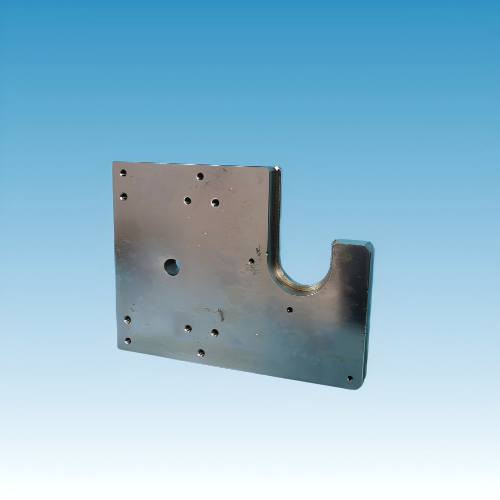

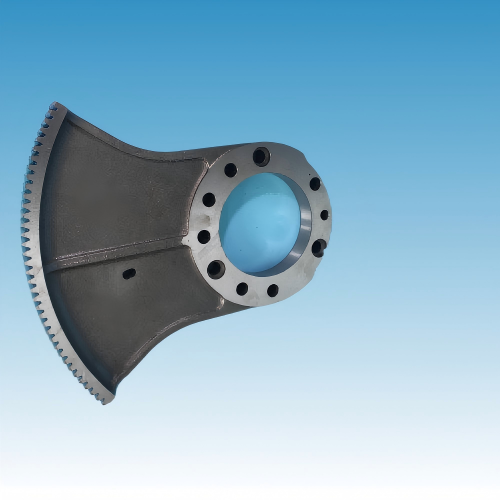

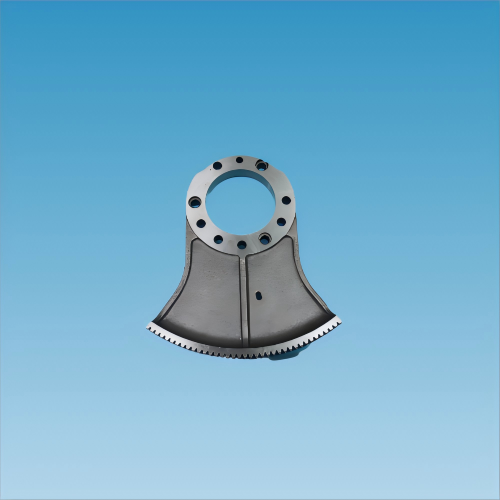

繊維機械用セクターギアカスタム非標準OEMギア

名前

モデル

材料

最小注文数量

配達

サンプル

起源地

サービス

アドバンテージ

名前

セクターギア

モデル

モデル: SC205FZ2025

材料

材質:20CrMnTi

最小注文数量

MOQ: ご要望に応じて

配達

配送: 数量に応じて

サンプル

サンプル: サンプル提供

起源地

原産地: 中国浙江省

サービス

サービス: OEM ODM カスタマイズ

アドバンテージ

利点: プロフェッショナルチーム 高品質

繊維機械におけるセクターギアの特徴と機能

-

部分ギア形状:

- 完全な円形ギアとは異なり、 セクターギア 円の一部のような形をしています。 曲線または円弧状の形状 特定の角度範囲でギアと噛み合うことができます。この設計は、部分的な回転や繊維機械内の特定の機能を必要とするアプリケーションに最適です。

-

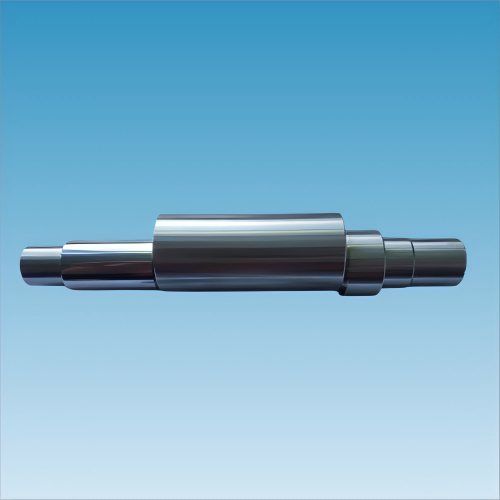

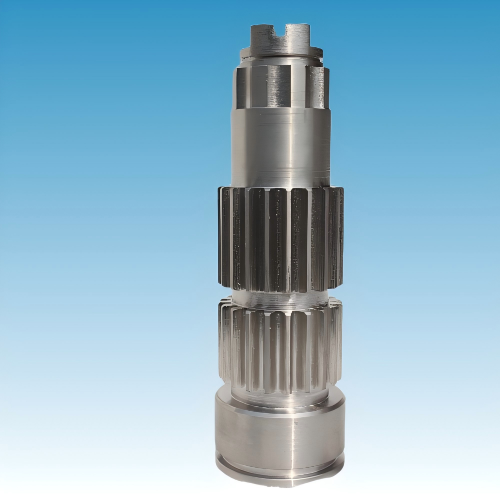

電力伝送における役割:

- 繊維機械のさまざまな部品間で回転運動と動力を伝達する上で重要な役割を果たします。他のギア (平歯車、ピニオン、ラックなど) と噛み合って、スピンドル、ローラー、フィード機構などのさまざまなコンポーネントを駆動します。

-

繊維機械への応用:

- 幅広い繊維機械に使用されている

これらのギアは、機械内のさまざまな動きを同期させ、正確でスムーズな操作を保証します。

-

素材と耐久性:

- 繊維機械のそれらは、通常、次のような耐久性のある材料で作られています。 鋼、鋳鉄、または硬化合金 継続的な使用による摩耗に耐えます。場合によっては、摩擦を減らして寿命を延ばすために、ギアを複合材料で作ったり、コーティング処理したりすることもあります。

-

速度とトルクの制御:

- 設計と用途に応じて、セクターギアは次の用途に使用できます。 増加 または 速度を落とす、または調整する トルク 伝達されます。これは、巻き取り、整経、編みなど、生産のさまざまな段階で速度と出力を正確に制御する必要がある繊維機械では特に重要です。

-

精度とタイミング:

- 多くの繊維加工工程では、機械部品の正確なタイミングと同期が必要です。機械部品は、他のギアと制御された方法で噛み合うことでこれを実現します。正確なステッチ形成、材料供給、張力制御が不可欠な機械では、これが極めて重要です。

-

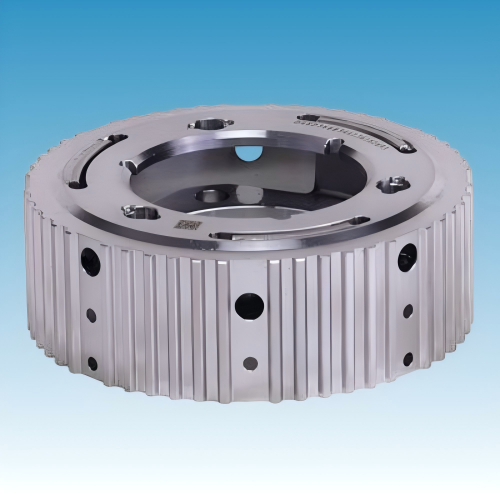

スペース効率:

- 円の一部のみを占めるため、よりコンパクトな設計にフィットし、ギア システム用のスペースが限られているマシンに最適です。

-

精度と信頼性:

- これらは特定の正確な動作用に設計されており、機械部品の正確な制御と同期を必要とするアプリケーションで高い信頼性を発揮します。

-

カスタマイズ性:

- 希望する動きやタイミングに合わせてセクターの弧やサイズを調整するなど、機械の特定のニーズに合わせてカスタマイズできます。

-

効率的な動力伝達:

- これらのギアは、機械内での動力の効率的な伝達を提供し、スムーズな動作を保証し、機械の故障やエネルギー損失の可能性を減らします。

-

過酷な環境でも耐久性を発揮:

- 繊維製品は高速で摩擦を伴うことが多いため、こうした過酷な環境に耐えられるように作られており、長期的な耐久性を確保しています。

結論:

セクターギア のために 大型レピアマシン 繊維機械の設計と操作に不可欠なコンポーネントです。その機能は、動力を伝達し、機械のさまざまな部分を正確に同期させることで、繊維生産プロセス全体のスムーズで効率的な操作を確保することです。スピンドルの速度制御から織りや編みの要素の動きの調整まで、繊維機械の性能と信頼性を維持する上で重要な役割を果たします。