- WENLING ZHEJIANG CHINA

- [email protected]

- 86 18958695512

- Home

- PRODUCT

- Contruction machinery components

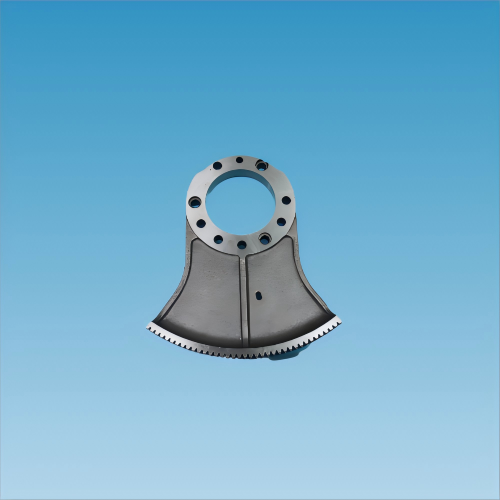

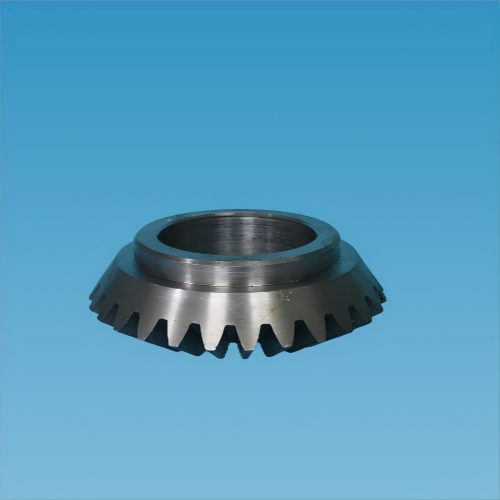

- Mine equipment spare parts gear high accurate cnc spur gear

Mine equipment spare Parts gear high accurate cnc spur gear

Mine Equipment Spare Parts gear wheel highly Accurate Cnc Gear Stainless Steel Aluminum Metal Spur Gear high quality Transmission Gear Shaft cnc manufacturing service Oem mine Accessories High Quality High Precision Manufacturer Spur Gear

SC205KJ5002

Mine equipment spare parts refer to the replacement components used to maintain, repair, and ensure the proper functioning of machinery and equipment in mining operations. These spare parts are critical to the continuous operation of mining equipment, as mining machinery operates under harsh and demanding conditions, and components can wear out or break over time due to constant use, exposure to dust, heat, vibration, and heavy loads.

NAME: MINE EQUIPMENT SPARE PARTS

MODEL: SC205KJ5002

MATERIAL:STEEL,COPPER

MOQ: AS YOUR REQUIREMENT

DELIVERY: ACCORDING TO YOUR QUANTITY

SAMPLE: SAMPLE OFFERED

ORIGIN PLACE: ZHEJANG CHINA

SERVICE: OEM ODM CUSTOMIZED

ADVANTAGE: PROFESSIONAL TEAM HIGH QUALITY

Types of Mining Equipment Spare Parts

Mine equipment spare parts refer to the replacement components used to maintain, repair, and ensure the proper functioning of machinery and equipment in mining operations. These spare parts are critical to the continuous operation of mining equipment, as mining machinery operates under harsh and demanding conditions, and components can wear out or break over time due to constant use, exposure to dust, heat, vibration, and heavy loads.

Types of Mining Equipment Spare Parts:

Drilling Equipment Spare Parts:

- Drill bits: Used in drilling machines for creating boreholes in the earth.

- Drill rods: Long, hollow tubes used to extend the drill bit into the ground.

- Hammer assemblies: Parts of pneumatic or hydraulic drills used for impact drilling.

Excavators and Loaders Spare Parts:

- Buckets: Attachments used to scoop and transport material.

- Hydraulic cylinders: Components responsible for the lifting and movement of the equipment.

- Track pads: Parts of the undercarriage that allow the excavator or loader to move efficiently on rough terrain.

- Filters: Air, oil, and fuel filters to keep machinery running smoothly.

Conveyor Systems Spare Parts:

- Conveyor belts: Rubber or metal belts used to transport materials.

- Idlers and rollers: Support components that guide and tension the conveyor belt.

- Pulleys and drums: Used to drive and change the direction of the conveyor belt.

Crushing and Screening Equipment Spare Parts:

- Jaw plates: Replaceable parts in crushers used to break down rocks.

- Cones and mantles: Parts used in cone crushers for further reduction of material size.

- Screen meshes: Used in vibrating screens to separate materials by size.

Mining Trucks and Haulers Spare Parts:

- Engine components: Such as pistons, gaskets, and bearings.

- Transmission parts: Gearboxes, clutches, and differential parts.

- Suspension parts: Springs, shock absorbers, and axles.

Ventilation Equipment Spare Parts:

- Fans: Used for air circulation and ventilation in underground mining operations.

- Air filters: To keep the ventilation system clean and efficient.

- Ducting and piping: Parts that direct and distribute the airflow throughout the mine.

Pumps and Compressors Spare Parts:

- Pump seals: Prevent leaks and maintain pump efficiency.

- Impellers: Rotate to move fluids through a pump.

- Compressor valves: Used in air or gas compression systems.

Electrical Components:

- Circuit breakers: Protect electrical circuits from damage.

- Motors and alternators: Power equipment and systems.

- Wiring and connectors: Used for electrical connections throughout the equipment.

Importance of Spare Parts in Mining Operations:

- Downtime Minimization: Mining operations often run 24/7, and downtime due to equipment failure can result in significant production losses. Having spare parts available ensures that broken or worn-out parts can be replaced quickly, minimizing downtime.

- Equipment Longevity: Regular maintenance and the replacement of worn parts with high-quality spares can extend the life of mining equipment.

- Safety: Malfunctioning equipment can lead to safety hazards for workers. Replacing damaged or worn-out parts ensures the equipment remains safe to use.

- Cost Efficiency: Proactive replacement of parts before failure can reduce the cost of emergency repairs and extend the operational life of expensive mining machinery.

Where Spare Parts Are Sourced:

- OEMs (Original Equipment Manufacturers): The manufacturers of mining equipment often provide spare parts that are specifically designed for their machinery.

- Aftermarket Suppliers: These suppliers offer parts that are compatible with various brands of mining equipment, and they may provide cost-effective alternatives to OEM parts.

- Local Distributors and Dealers: Many mining operations source spare parts from local suppliers or dealers to reduce delivery time and costs.

In summary, mine equipment spare parts are essential for maintaining the functionality, safety, and efficiency of machinery used in mining operations. Regular maintenance and timely replacement of worn-out or damaged parts are crucial for maximizing productivity and reducing the risk of expensive breakdowns.

Shenchi technology co.,is a professional OEM machinery factory located in weneling zhejiang,China. The main business includes CNC turning and milling parts, CNC machining center parts; etc.We can complete the mold product, logo customization and finish services including sandblasting, powder coating, anodizing, electroplating, polishing and laser etching.

©2024. Shenchi Company All Rights Reserved.