- WENLING ZHEJIANG CINA

- [email protected]

- 86 18958695512

- Casa

- NOTIZIE AZIENDALI

- Pagine

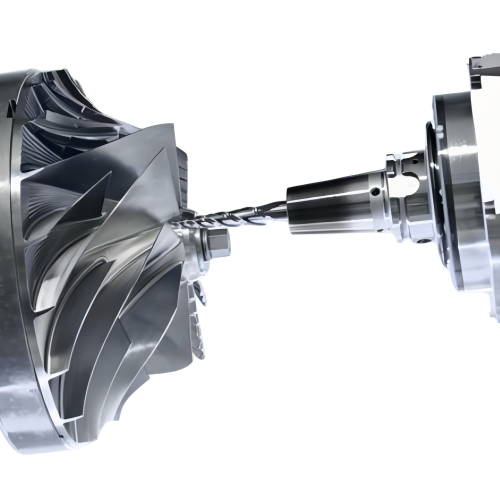

- Precision CNC Milling Machine Equipment super Accuracy 5axis

Precision CNC Milling Machine Parts Manufacturer: Your Trusted Partner High-Quality Machined Components

shenchi is a leading manufacturer of high-precision CNC machined components, specializing in advanced CNC milling machine services for aerospace, automotive, medical, and energy industries. With over 20 years of machining expertise, we combine state-of-the-art 5-axis milling technology with rigorous quality control to deliver components that meet the most demanding international standards.

In today’s competitive manufacturing landscape, precision and reliability are non-negotiable. As a leading CNC milling machine parts manufacturer, we specialize in producing high-accuracy, custom-machined components for industries ranging from aerospace and automotive to medical and industrial machinery. With state-of-the-art CNC milling technology, rigorous quality control, and a commitment to excellence, we deliver precision-engineered parts that meet the most demanding international standards.

Whether you need prototypes, small-batch production, or large-scale OEM/ODM machining services, our factory is equipped to handle complex geometries, tight tolerances, and diverse material requirements. This article highlights our manufacturing capabilities, quality assurance processes, and competitive advantages to help global buyers make an informed decision when sourcing CNC milled parts.

1. Advanced CNC Milling Capabilities for Precision Parts

Our factory is equipped with multi-axis CNC milling machines (3-axis, 4-axis, and 5-axis) to produce intricate components with micron-level accuracy. We work with a wide range of materials, including:

Metals: Aluminum, Stainless Steel, Titanium, Brass, Copper, Carbon Steel

Plastics: POM, PTFE, Nylon, ABS, PVC, Polycarbonate

Exotic Alloys: Inconel, Hastelloy, Monel, Magnesium

Key CNC Milling Services:

High-Speed Machining – For fine finishes and tight tolerances (±0.005mm)

✔ Prototype & Low-Volume Production – Rapid turnaround for testing and validation

✔ Complex 5-Axis Milling – For contoured surfaces and intricate geometries

✔ Micro-Machining – Precision parts for medical and electronics industries

✔ Custom Finishing – Anodizing, Powder Coating, Plating, Polishing

Our CNC milling expertise ensures that every part meets exact specifications, whether for automotive transmissions, aerospace actuators, hydraulic systems, or robotics components.

2. Quality Assurance & Certifications

To guarantee zero-defect machining, we implement a stringent quality management system backed by:

ISO 9001:2015 Certification – Ensuring consistent quality control

Advanced Metrology Equipment – CMM (Coordinate Measuring Machine), Optical Comparators, Surface Roughness Testers

Material Traceability – Full documentation for material certifications (MTRs)

First-Article Inspection (FAI) & PPAP – For compliance with automotive & aerospace standards

We also perform 100% dimensional inspection on critical components, ensuring that every batch meets ASME, DIN, or JIS standards as required by global buyers.

3. Industries We Serve

Our CNC milled parts are trusted by leading manufacturers across multiple sectors:

Aerospaziale e difesa

Aircraft structural components

Landing gear parts

UAV (Drone) components

Automotive & Motorsports

Engine blocks & transmission housings

Suspension & braking system parts

EV (Electric Vehicle) battery enclosures

Medical & Dental Equipment

Surgical instruments

Implantable devices

MRI & CT scanner components

Macchinari industriali e automazione

Hydraulic valves & pumps

Robotics arms & linear guides

Mold & die components

Energy & Oil & Gas

Valve bodies & manifolds

Turbine blades

Offshore drilling equipment

No matter the industry, we provide durable, high-precision CNC milled parts that enhance performance and longevity.

4. Why Choose Us as Your CNC Milling Parts Supplier?

Competitive Pricing Without Compromising Quality

By optimizing machining processes and maintaining in-house tooling capabilities, we offer cost-effective solutions for both prototypes and mass production.

Fast Lead Times & Reliable Logistics

With streamlined production and partnerships with global freight forwarders, we ensure on-time delivery to the USA, Europe, and Asia.

Engineering Support & DFM (Design for Manufacturing) Feedback

Our team provides free design optimization suggestions to reduce costs and improve manufacturability.

Flexible Order Quantities

From 1-piece prototypes to 100,000+ unit production runs, we scale according to your demand.

Strict Confidentiality & IP Protection

We sign NDAs and ensure all customer designs remain secure.

5. Case Study: High-Precision CNC Milled Component for Aerospace

Client Requirement: A leading aerospace manufacturer needed titanium mounting brackets with a tolerance of ±0.01mm and a mirror-like surface finish.

Our Solution:

Used 5-axis CNC milling for complex contours

Applied ultra-high-speed machining to minimize tool marks

Conducted CMM inspection to validate dimensions

Provided anodized coating for corrosion resistance

Result: The parts passed AS9100D inspection and were delivered within 4 weeks, earning long-term partnership status.

6. Partner with Us for Your Next CNC Milling Project

As a trusted CNC milling parts manufacturer, we combine cutting-edge technology, skilled engineers, and a customer-first approach to deliver superior machined components.

Let’s discuss how we can meet your precision machining needs with quality, reliability, and competitive pricing!

Conclusione

In the world of precision CNC milling, expertise and technology make all the difference. Our factory is committed to delivering high-accuracy, durable machined parts that help global manufacturers stay ahead. Whether you need prototyping, low-volume batches, or full-scale production, we have the capabilities to be your long-term machining partner.

Reach out today—let’s engineer excellence together!

Shenchi technology co., è un professionista Fabbrica di macchinari OEM situato a Wenling Zhejiang, Cina. L'attività principale comprende parti di tornitura e fresatura CNC, parti di centri di lavorazione CNC, ecc. Possiamo completare il prodotto dello stampo, la personalizzazione del logo e i servizi di finitura, tra cui sabbiatura, verniciatura a polvere, anodizzazione, galvanica, lucidatura e incisione laser.

© Shenchi Company Tutti i diritti riservati.