- WENLING ZHEJIANG CINA

- alamat email:shenchimachinery.com

- 86 18958695512

- Rumah

- PRODUK

- Komponen produk lainnya

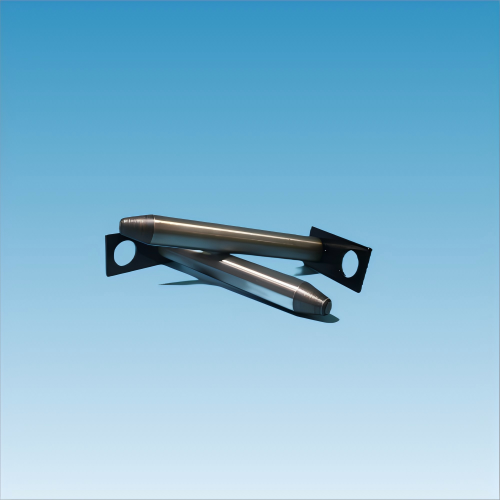

- Piston pump High Quality Agriculture Machinery Plunger pump

Piston pump High Quality Agriculture Machinery Plunger pump

As a professional manufacturer of piston pumps untuk agricultural machinery parts, we specialize in producing durable and high-performance hydraulic components that keep farming equipment running smoothly. Our plunger pump solutions are engineered to meet the rigorous demands of modern agriculture, offering exceptional value through competitive pricing and customizable designs.

Why Choose Our Piston Pumps?

Superior Durability

Teknik Presisi

Custom Solutions

Cost Advantage

NAME: Piston pump

MODEL:SC205JD-AC1002

BAHAN: IKUTI KEBUTUHAN ANDA

MOQ: SESUAI KEBUTUHAN ANDA

PENGIRIMAN: SESUAI DENGAN JUMLAH ANDA

CONTOH: CONTOH YANG DITAWARKAN

TEMPAT ASAL: ZHEJANG CHINA

LAYANAN: OEM ODM YANG DISESUAIKAN

KELEBIHAN: TIM PROFESIONAL BERKUALITAS TINGGI

Premium Piston Pumps for Agricultural Machinery: Custom, High-Performance Solutions at Competitive Prices

In modern agriculture, reliable hydraulic systems are the backbone of efficient farming operations. As a leading manufacturer of piston pumps untuk agricultural machinery parts, we specialize in delivering high-performance, durable, and cost-effective fluid power solutions. Our expertise in plunger pump technology ensures that tractors, harvesters, and irrigation systems operate at peak efficiency, even under the most demanding conditions.

This article highlights our factory’s professional engineering capabilities, customization options, Dan unbeatable pricing—making us the preferred partner for agricultural equipment manufacturers and distributors worldwide.

1. The Critical Role in Agricultural Machinery

Piston pumps (including plunger pumps) are essential for powering hydraulic systems in:

Tractors & Harvesters – Driving attachments like loaders, balers, and seeders.

Irrigation Systems – Delivering high-pressure water for pivot/sprinkler systems.

Sprayers & Fertilizer Spreaders – Ensuring precise chemical application.

Why Our Pumps Stand Out:

High Pressure (up to 450 bar) – Maintains consistent flow under heavy loads.

Efficiency (≥92%) – Reduces fuel consumption and operational costs.

Daya tahan – Hardened steel construction resists wear from abrasive fluids.

2. Our Factory’s Professional Expertise

With 15+ years in hydraulic manufacturing, we combine advanced technology with stringent quality control:

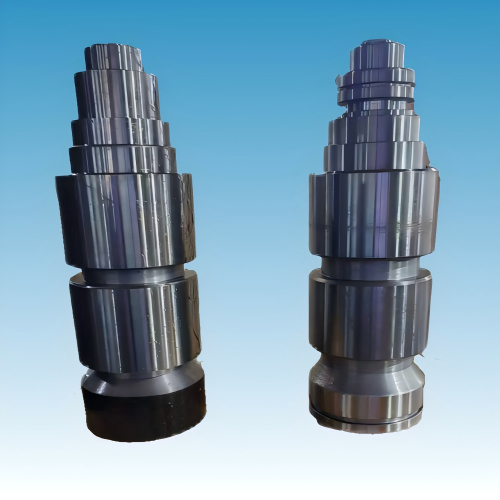

A. Precision Engineering

CNC machining ensures tolerances within ±0.01mm.

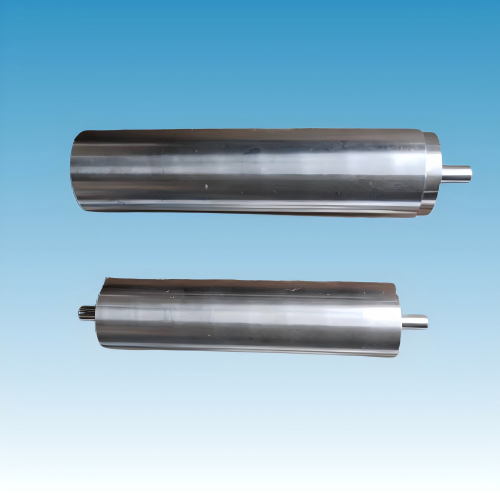

Automated grinding/polishing for smooth piston/cylinder surfaces.

B. Rigorous Testing

100% pressure cycling tests (0–450 bar, 50,000+ cycles).

Leakage checks with helium detection (<0.1 cc/min).

C. Certifications

ISO 9001 – Quality management system.

CE & RoHS – Compliance for EU markets.

3. Customization for Every Agricultural Application

We design to your machinery’s needs:

A. Material Options

B. Performance Customization

Flow Rates: 5–200 L/min.

Port Configurations: SAE, BSPP, DIN flanges.

Mounting Types: Foot, flange, or split coupling.

Case Study: A European harvester manufacturer reduced pump failures by 60% after switching to our ceramic-plated plunger pumps.

4. Unbeatable Price-to-Performance Ratio

We cut costs—not corners—through:

Vertical Integration – In-house casting/machining lowers production costs.

Economies of Scale – Annual output of 50,000+ pumps ensures competitive pricing.

Direct Factory Pricing – No middlemen; savings passed to you.

5. Industries & Applications

Crop Farming – Combine harvesters, planters.

Livestock – Feed mixers, manure spreaders.

Precision Ag – Autonomous sprayer drones.

Why Farmers Trust Us:

30% longer service life vs. industry average.

24/7 technical support for troubleshooting.

6. Easy Ordering Process

Share Requirements – Flow, pressure, material preferences.

Receive Proposal – CAD drawings + quote in 2 days.

Test Samples – Approve prototypes before mass production.

Delivery – 30–45 days lead time; EXW/FOB/DDP terms.

wwelcome to contact us sample

Shenchi technology co., adalah perusahaan profesional Pabrik mesin OEM berlokasi di Wenling, Zhejiang, Tiongkok. Bisnis utamanya meliputi suku cadang bubut dan penggilingan CNC, suku cadang pusat permesinan CNC, dll. Kami dapat menyelesaikan produk cetakan, kustomisasi logo, dan layanan penyelesaian termasuk sandblasting, pelapisan serbuk, anodisasi, pelapisan listrik, pemolesan, dan pengetsaan laser.

Berlangganan Sekarang

Jangan lewatkan pembaruan kami selanjutnya! Berlanggananlah Hari Ini!

© Shenchi Company Seluruh Hak Dilindungi Undang-Undang.