- Wenling, Zhejiang, China

- [email protected]

- 86 18958695512

- Hogar

- PRODUCTO

- Auto components

- Páginas

- Charge pump Good Quality Transmission Engineering Vehicles 1

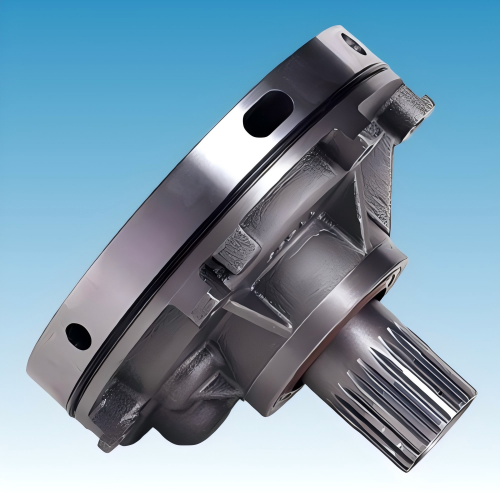

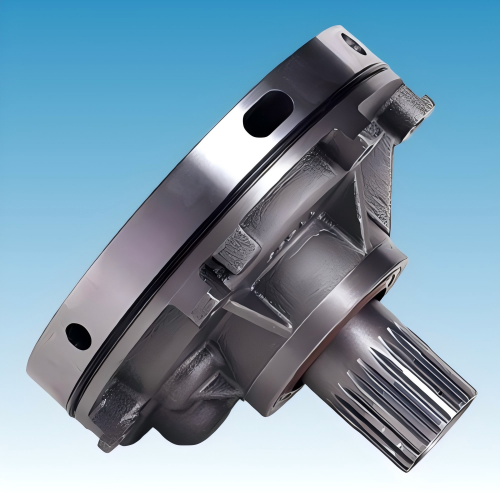

Charge pump Good Quality Transmission Engineering Vehicles

charge pump (also called a fuel feed pump o transfer pump) is a critical component in fuel systems, particularly in diesel engines and high-performance machinery. Its primary function is to deliver fuel from the tank to the injection system at the required pressure, ensuring optimal combustion and engine performance.

Upgrade your engineering vehicle’s fuel system with our solutions—where performance meets reliability!

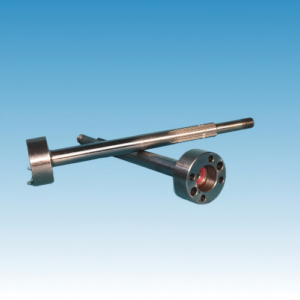

NAME: Charge pump

MODEL:SC205JD-GGC1016

MATERIAL: SIGA SUS REQUISITOS

MOQ: SEGÚN SU REQUISITO

ENTREGA: SEGÚN SU CANTIDAD

MUESTRA: MUESTRA OFRECIDA

LUGAR DE ORIGEN: ZHEJANG, CHINA

SERVICIO: OEM ODM PERSONALIZADO

VENTAJA: EQUIPO PROFESIONAL DE ALTA CALIDAD

The Ultimate Guide to Fuel Supply Pump Components for Engineering Vehicles

Fuel supply pumps are the lifeline of engineering vehicles, ensuring optimal engine performance and efficiency. Whether it’s a bulldozer, excavator, or dump truck, a reliable change pump system is critical for smooth operations. This comprehensive guide explores the key components of fuel supply pumps, the process of change pump units, and best practices for maintaining these vital systems in engineering vehicles.

1. Understanding Fuel Supply Pumps for Engineering Vehicles

Fuel supply pumps, also known as feed pumps or transfer pumps, are responsible for delivering fuel from the tank to the engine. In engineering vehicles, these pumps must withstand harsh conditions, including extreme temperatures, heavy loads, and prolonged operation.

Key Functions:

Fuel Delivery – Ensures consistent fuel flow to the engine.

Pressure Regulation – Maintains optimal pressure for combustion.

Filtration Support – Works with fuel filters to prevent contaminants from entering the engine.

2. Essential Components of a Fuel Supply Pump

A fuel supply pump consists of several critical parts that ensure efficient performance.

A. Pump Housing

Hecho de durable aluminum or cast iron to resist corrosion and high pressure.

Protects internal components from dust, debris, and mechanical damage.

B. Electric or Mechanical Drive

Electric pumps (common in modern engineering vehicles) use a motor for precise fuel control.

Mechanical pumps (often gear-driven) are robust and suitable for heavy-duty applications.

C. Impeller or Gear Mechanism

Creates suction to draw fuel from the tank.

Gear pumps are common in diesel engines for high-pressure fuel delivery.

D. Pressure Relief Valve

Prevents excessive pressure buildup that could damage the fuel system.

Critical for maintaining engine efficiency and preventing leaks.

E. Inlet/Outlet Ports

Designed for secure hose connections to avoid fuel leaks.

Compatible with standard engineering vehicle fuel line fittings.

F. Seals & Gaskets

High-quality rubber or synthetic seals prevent fuel leakage.

Must be resistant to diesel, biodiesel, and extreme temperatures.

3. When and How to Perform a Pump Change

Over time, wear and tear can reduce pump efficiency. Knowing when and how to perform a changing pump procedure is crucial for vehicle maintenance.

Signs You Need a Pump Change:

⚠ Engine Sputtering – Inconsistent fuel flow indicates pump failure.

Loss of Power – Weak acceleration due to insufficient fuel pressure.

Unusual Noises – Whining or grinding sounds from the pump.

Fuel Leaks – Visible drips near the pump housing.

Step-by-Step Pump Replacement Process:

Depressurize the System – Disconnect the battery and relieve fuel pressure.

Disconnect Fuel Lines – Use proper tools to avoid spills.

Remove the Old Pump – Unbolt the housing and extract the faulty unit.

Install the New Pump – Ensure proper alignment and secure connections.

Prime the System – Refill and bleed air from the fuel lines.

Test Operation – Start the engine and check for leaks or irregularities.

4. Choosing the Right Replacement Pump for Engineering Vehicles

Not all pumps are created equal. Consider these factors when selecting a change pump:

Compatibility – Match OEM specs for pressure and flow rate.

Durabilidad – Look for corrosion-resistant materials.

Eficiencia – High-performance pumps reduce fuel consumption.

Brand Reliability – Trusted manufacturers ensure longer service life.

5. Maintenance Tips to Extend Pump Life

Regular Inspections – Check for leaks, noise, and pressure drops.

Clean Fuel Filters – Clogged filters force the pump to work harder.

Use Quality Fuel – Contaminants accelerate wear.

Monitor Fuel Levels – Running on low fuel can overheat the pump.

6. Why Choose Our Fuel Supply Pumps?

As a leading manufacturer for engineering vehicles, we provide:

High-Precision Pumps – Engineered for heavy-duty applications.

Custom Solutions – Tailored flow rates and pressure settings.

Fast Global Shipping – Reliable supply for fleet operators.

OEM & Aftermarket Options – Perfect fit for various vehicle models.

Shenchi technology co., es una empresa profesional Fábrica de maquinaria OEM Ubicada en Wenling, Zhejiang, China. Nuestra actividad principal incluye piezas de torneado y fresado CNC, piezas para centros de mecanizado CNC, etc. Ofrecemos moldes, personalización de logotipos y servicios de acabado, como arenado, recubrimiento en polvo, anodizado, galvanoplastia, pulido y grabado láser.

Suscríbete ahora

¡No te pierdas nuestras próximas actualizaciones! ¡Suscríbete hoy!

© Shenchi Company Todos los derechos reservados.