- Wenling, Zhejiang, China

- [email protected]

- 86 18958695512

- Hogar

- PRODUCTO

- Componentes de maquinaria de construcción

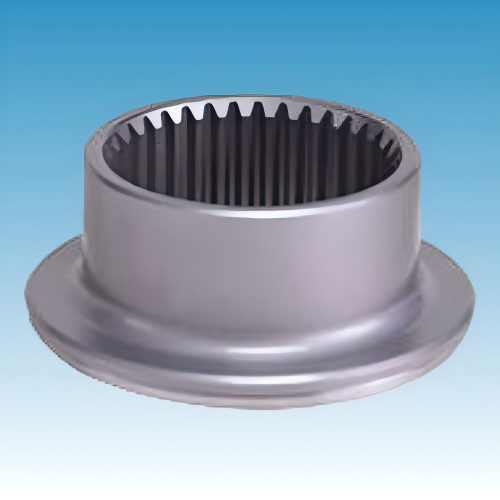

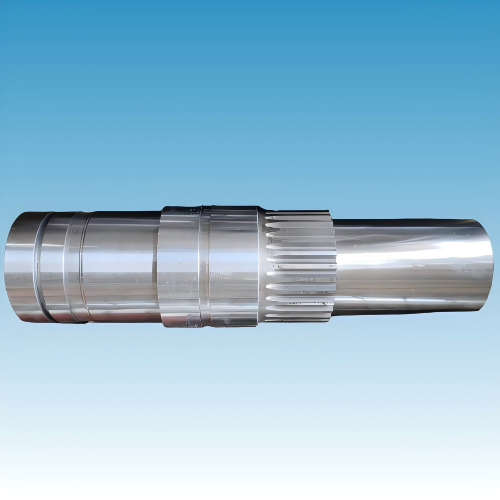

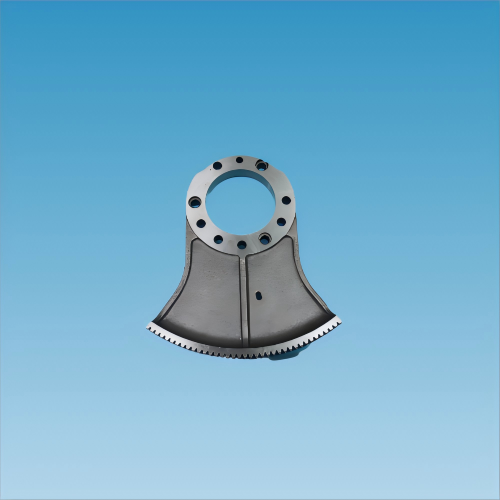

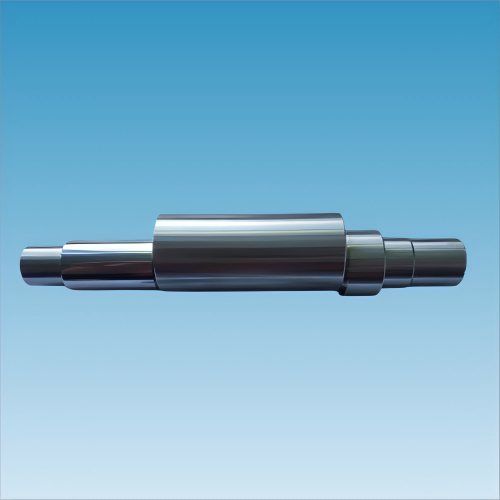

- Pieza de accionamiento CNC de construcción personalizada con eje de precisión OEM

Eje de precisión OEM, construcción personalizada, piezas de accionamiento CMC

Eje de precisión OEM Componentes de eje de acero personalizados Precio de fábrica Mecanizado de maquinarias para ejes de metal Construcción CNC personalizada con certificación ISO Piezas de eje de transmisión

SC205GC5008

Eje de precisión OEM se refiere a una eje Fabricados con altos niveles de precisión y exactitud, generalmente producidos para Fabricante de equipos originales Aplicaciones (OEM). El término OEM se refiere a empresas que fabrican productos o componentes que se utilizan en productos terminados de otros fabricantes. Por lo tanto, un eje de precisión OEM es un componente diseñado y fabricado según especificaciones exactas para adaptarse a equipos o maquinaria específicos fabricados por el OEM.

NOMBRE: Eje de precisión OEM

MODELO: SC205GC5008

MATERIAL:ACERO

MOQ: SEGÚN SU REQUISITO

ENTREGA: SEGÚN SU CANTIDAD

MUESTRA: MUESTRA OFRECIDA

LUGAR DE ORIGEN: ZHEJANG, CHINA

SERVICIO: OEM ODM PERSONALIZADO

VENTAJA: EQUIPO PROFESIONAL DE ALTA CALIDAD

Beneficios de los ejes de precisión OEM

Alta precisión:

- Ejes de precisión Se fabrican con tolerancias estrictas, lo que significa que se fabrican con un alto grado de precisión. Esto garantiza que el eje se ajuste perfectamente a la maquinaria o sistema para el que está diseñado, reduciendo el riesgo de mal funcionamiento o ineficiencia. Procesos de mecanizado de precisión como... Torneado y rectificado CNC, o molienda Se utilizan a menudo para lograr el nivel de precisión requerido.

Materiales:

- Los ejes de precisión OEM generalmente están fabricados con materiales de alta calidad como acero inoxidable, acero carbono, acero aleado, acero para herramientas, o latónLa elección del material depende de la aplicación específica, los requisitos de durabilidad y los factores ambientales (como la exposición a la humedad, productos químicos o temperaturas extremas).

Durabilidad:

- Estos ejes están diseñados para soportar altas tensiones, fuerzas de torsión y desgaste durante largos periodos. El uso de materiales de alta resistencia y una fabricación precisa garantizan que el eje pueda soportar las cargas y tensiones a las que se somete en su aplicación específica.

Ajuste personalizado:

- Los ejes de precisión OEM suelen estar diseñados y fabricados específicamente para un equipo o sistema específico. Esto garantiza... ajuste perfecto y una funcionalidad óptima, ya sea en motores, sistemas de engranajes, turbinas, u otros tipos de maquinaria.

Aplicaciones:

- Industria automotriz:Los ejes de precisión se utilizan en diversos componentes automotrices, como transmisiones, ejes de transmisión y ejes de ruedas.

- Maquinaria industrial:Estos ejes son comunes en transportadores, sistemas robóticos, y zapatillas, donde el alto rendimiento y la confiabilidad son cruciales.

- Aeroespacial:Los ejes de precisión también se utilizan ampliamente en motores de aeronaves y otros equipos aeroespaciales, donde se requieren tolerancias extremas para la seguridad y el rendimiento.

- Electrónica:Algunos ejes de precisión OEM se utilizan en motores y otras piezas mecánicas Para dispositivos y electrónica de consumo.

Personalización:

- Los ejes de precisión OEM se pueden personalizar en términos de tamaño, longitud, forma, y acabado superficial (p. ej., pulido o revestido) para satisfacer las necesidades del equipo específico. La personalización garantiza que el eje funcione eficientemente dentro de las limitaciones y requisitos del sistema.

Procesos de fabricación:

Mecanizado CNC:

- Control numérico por computadora (CNC) Las máquinas se utilizan comúnmente para fabricar ejes de precisión. Estas máquinas están programadas para realizar tareas como torneado, fresado, taladrado y rectificado, garantizando tolerancias estrictas y superficies lisas.

Molienda:

- Después del mecanizado inicial, los ejes pueden sufrir molienda Para eliminar cualquier imperfección y lograr un acabado superficial extremadamente liso y preciso. Esto es esencial para reducir la fricción y el desgaste durante el funcionamiento.

Tratamiento térmico:

- Tratamiento térmico procesos tales como temple o templado Puede usarse para aumentar la dureza o resistencia del eje, garantizando que pueda soportar cargas pesadas y resistir el desgaste a lo largo del tiempo.

Recubrimientos de superficies:

- Algunos ejes de precisión OEM están recubiertos con materiales como cromo, níquel, o fosfatación para mejorar la resistencia a la corrosión y aumentar la vida útil del eje, especialmente en entornos hostiles.

Beneficios de los ejes de precisión OEM:

Rendimiento mejorado:

- Al garantizar que el eje se ajuste perfectamente a la maquinaria, los ejes de precisión OEM contribuyen al rendimiento general. actuación y eficiencia del sistema.

Mayor vida útil:

- Debido a su alta precisión y al uso de materiales de calidad, estos ejes tienden a tener una vida útil más larga, reduciendo la necesidad de reemplazos frecuentes.

Tiempo de inactividad reducido:

- La alta calidad y precisión de los ejes OEM ayudan a prevenir fallas o mal funcionamiento, minimizando falta del tiempo y los costos de mantenimiento de la maquinaria.

Eficiencia de costos:

- Si bien las piezas OEM pueden ser más caras inicialmente, su durabilidad, precisión y la reducción en mantenimiento y reemplazos a menudo resultan en ahorros de costos a largo plazo.

Consistencia:

- Los ejes de precisión OEM garantizan calidad constante y el rendimiento en diferentes lotes del mismo equipo. Esto es fundamental en industrias donde la fiabilidad de las máquinas es primordial.

Ejemplos de aplicaciones:

Ejes de transmisión automotrices:

- En los vehículos, ejes de transmisión Transmiten el par del motor a las ruedas. Los ejes de transmisión de precisión garantizan una transmisión de potencia suave y eficiente, reduciendo las vibraciones y mejorando el rendimiento general del vehículo.

Motores eléctricos:

- Los ejes de precisión se utilizan en motores eléctricos Para transferir la fuerza rotacional del rotor del motor a otros componentes como engranajes, bombas o compresores. La alta precisión garantiza un funcionamiento eficiente del motor y un desgaste óptimo.

Sistemas de engranajes industriales:

- En sistemas de engranajesLos ejes de precisión conectan engranajes y otras piezas móviles, garantizando un funcionamiento suave y fiable. El eje debe estar diseñado para soportar el alto par que suele presentarse en aplicaciones industriales.

Componentes aeroespaciales:

- En la industria aeroespacial, los ejes de precisión se utilizan en diversos sistemas mecánicos, como turbinas y motores, donde la tolerancia y el rendimiento son fundamentales para la seguridad y la confiabilidad.

Conclusión:

Un Eje de precisión OEM Es un componente mecánico de alta precisión y calidad, diseñado para aplicaciones específicas en diversas industrias, como la automotriz, la aeroespacial, la maquinaria industrial y la electrónica. Estos ejes son fundamentales para garantizar el funcionamiento eficiente y fiable de equipos complejos, y su alta precisión, durabilidad y ajuste personalizado los hacen indispensables en aplicaciones OEM. Al centrarse en tolerancias exactas y materiales superioresEstos ejes contribuyen al rendimiento general de la máquina, reducen los costos de mantenimiento y garantizan una vida útil más larga del equipo.

Shenchi technology co., es una empresa profesional Fábrica de maquinaria OEM Ubicada en Wenling, Zhejiang, China. Nuestra actividad principal incluye piezas de torneado y fresado CNC, piezas para centros de mecanizado CNC, etc. Ofrecemos moldes, personalización de logotipos y servicios de acabado, como arenado, recubrimiento en polvo, anodizado, galvanoplastia, pulido y grabado láser.

Suscríbete ahora

¡No te pierdas nuestras próximas actualizaciones! ¡Suscríbete hoy!

© Shenchi Company Todos los derechos reservados.