- WENLING ZHEJIANG CHINA

- [email protected]

- 86 18958695512

- Heim

- PRODUKT

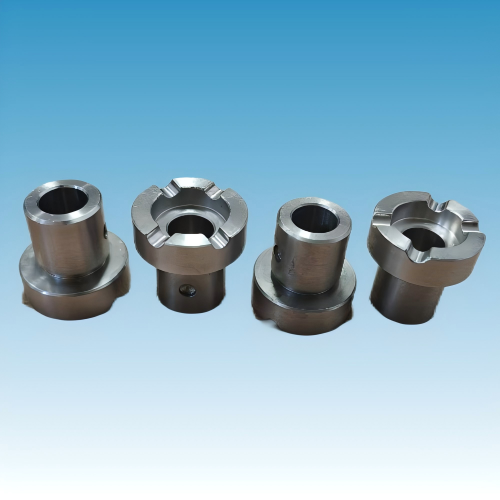

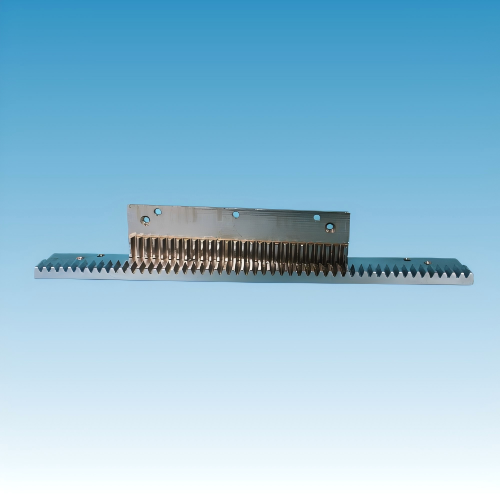

- Andere Produktkomponenten

- Hersteller von Vakuumpumpenwellen, hochwertige Präzisionswelle

Hersteller von Vakuumpumpenwellen, hochwertige Präzisionswelle

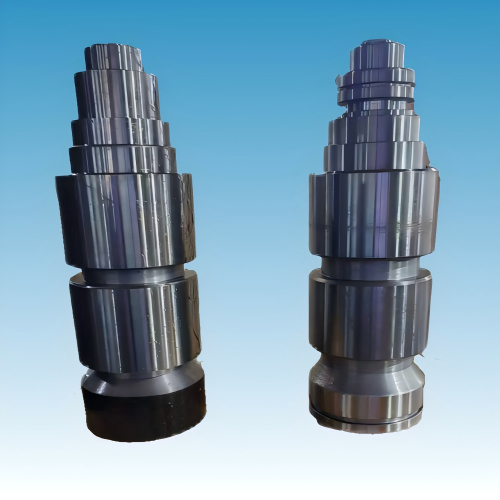

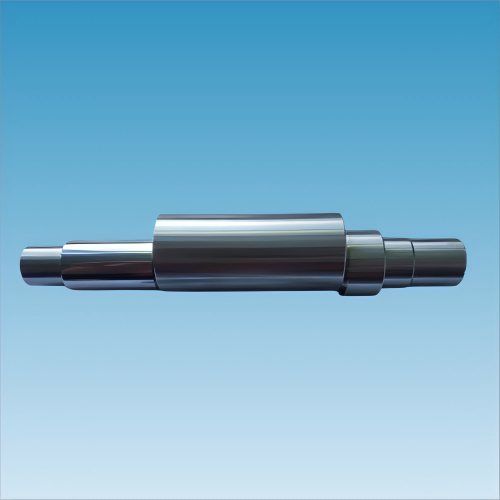

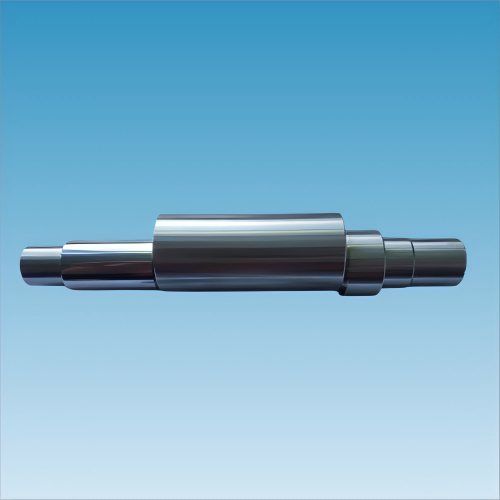

Vakuumpumpenwelle Hersteller OEM ODM Hochwertige Pumpenwellen für kundenspezifische Vakuumpumpenwellen Kundenspezifischer Bearbeitungsservice Präzisionswelle zum Fabrikpreis

SC205QT3025

A Vakuumpumpenwelle ist ein kritische rotierende Komponente in einem Vakuumpumpe, verantwortlich für Sendeleistung vom Motor zum Pumpenmechanismus. Es ermöglicht der Pumpe, Vakuumdruck durch effiziente Bewegung von Luft, Gas oder Flüssigkeiten.

NAME: Vakuumpumpenwelle

MODELL: SC205QT3025

MATERIAL: STAHL

MOQ: ALS IHRE ANFORDERUNG

LIEFERUNG: NACH IHRER MENGE

BEISPIEL: ANGEBOTENES MUSTER

URSPRUNGSORT: ZHEJANG, CHINA

SERVICE: OEM ODM ANGEPASST

VORTEIL: PROFESSIONELLES TEAM HOHE QUALITÄT

Warum ist die Vakuumpumpenwelle wichtig?

Vakuumpumpenwellen sind wesentliche Komponenten in verschiedenen Industrielle, automobile, medizinische und wissenschaftliche AnwendungenZu den Hauptabnehmern zählen:

1. Hersteller von Vakuumpumpen

Unternehmen, die Vakuumpumpen herstellen für industrielle, medizinische und kommerzielle Anwendungen.

Für die Montage zuverlässiger und effizienter Vakuumpumpen sind hochwertige Wellen erforderlich.

2. Hersteller von Industriemaschinen und -geräten

Branchen, die Vakuumpumpen verwenden in Produktionslinien, Materialhandhabung und -verarbeitung.

Beispiele: Lebensmittelverarbeitung, Pharmaindustrie, Chemieanlagen und Metallverarbeitung.

3. Automobilunternehmen und Zulieferer

Automobilhersteller und Zulieferer benötigen Vakuumpumpenwellen für:

- Bremsvakuumpumpen (für Servobremssysteme).

- Motorvakuumpumpen (für Kraftstoffeinspritzung und Emissionskontrolle).

Verwendet in Nutzfahrzeuge, LKW und Elektroautos.

4. HVAC- und Kältetechnikunternehmen

HVAC-Dienstleister (Heizung, Lüftung und Klimaanlagen) verwenden Vakuumpumpen für:

- Entfernen von Luft und Feuchtigkeit aus Klimaanlagen.

- Wartung von Kühlaggregaten und Vakuumisolierungen.

5. Hersteller von Medizin- und Laborgeräten

Vakuumpumpenwellen sind unverzichtbar bei:

- Medizinische Absaugpumpen (wird in Krankenhäusern zur Patientenversorgung verwendet).

- Labor-Vakuumsysteme (wird in der Forschung und beim Testen verwendet).

6. Luft- und Raumfahrt- und Verteidigungsunternehmen

Vakuumpumpen spielen eine entscheidende Rolle bei Flugzeugtriebwerkssysteme und Raumfahrttechnik.

Verteidigungs- und Weltraumforschungsorganisationen benötigen präzisionsgefertigte Vakuumpumpenwellen.

7. Reparatur- und Wartungsunternehmen

Unternehmen, die sich auf Reparatur und Wartung von Vakuumpumpen Ersatzwellen kaufen.

Sie dienen Fabriken, Krankenhäuser, Autowerkstätten und HLK-Unternehmen.

8. Lieferanten von Sondermaschinen und OEM-Teilen

Unternehmen, die liefern kundenspezifische Wellen für Hersteller von Vakuumpumpen.

Bedienen Sie spezialisierte Branchen, die hochpräzise Vakuumpumpenkomponenten.

Warum benötigen diese Käufer Vakuumpumpenwellen?

Zur Montage neuer Vakuumpumpen für verschiedene Anwendungen.

Zum Ersetzen verschlissener Wellen in bestehenden Vakuumpumpsystemen.

Zur Verbesserung von Effizienz und Haltbarkeit im Hochleistungs-Vakuumpumpenbetrieb.

Um Industriestandards zu erfüllen für Präzision, Sicherheit und Zuverlässigkeit.

Hauptfunktionen einer Vakuumpumpenwelle

Überträgt Rotationsbewegungen – Die Welle ist mit dem Motor verbunden und dreht sich, wodurch sie den internen Pumpenmechanismus antreibt.

Gewährleistet einen stabilen Pumpenbetrieb – Hilft, einen reibungslosen und ausgewogenen Betrieb aufrechtzuerhalten und Vibrationen zu reduzieren.

Unterstützt Hochgeschwindigkeitsrotation – Entwickelt, um Hochgeschwindigkeitsbewegungen ohne übermäßigen Verschleiß oder Ausfall zu bewältigen.

Funktioniert mit verschiedenen Vakuumpumpentypen – Verwendet in Drehschieber-, Flüssigkeitsring-, Membran- und andere Vakuumpumpen.

Häufig verwendete Materialien für Vakuumpumpenwellen

Edelstahl – Korrosionsbeständig und langlebig für industrielle Anwendungen.

Legierter Stahl – Bietet hohe Festigkeit und Verschleißfestigkeit.

Gehärteter Kohlenstoffstahl – Wird in Hochleistungsvakuumpumpen für zusätzliche Haltbarkeit verwendet.

Anwendungen von Vakuumpumpenwellen

Industrielle Vakuumpumpen – Wird in der Fertigung, Lebensmittelverarbeitung und Verpackung verwendet.

Automobilsysteme – In Bremssystemen, Motorvakuumpumpen und Klimaanlagen zu finden.

Medizinische und Laborgeräte – Wird in Absaugvorrichtungen und Vakuumkammern verwendet.

Klima- und Kältetechnik – Hilft, Luft und Feuchtigkeit aus Klimaanlagen zu entfernen.

Warum ist die Vakuumpumpenwelle wichtig?

Ermöglicht eine effiziente Pumpenleistung – Sorgt für eine gleichmäßige Kraftübertragung zur effektiven Vakuumerzeugung.

Reduziert Verschleiß – Eine gut konstruierte Welle minimiert Reibung und mechanische Belastung.

Unterstützt den Langzeitbetrieb – Hochwertige Materialien verbessern Haltbarkeit und Zuverlässigkeit.

Vakuumpumpenwellen werden gekauft von Pumpenhersteller, Industrie- und Automobilunternehmen, Hersteller medizinischer Geräte, Luft- und Raumfahrtunternehmen und WartungsdienstleisterIhre Rolle in Kraftübertragung, Effizienz und Haltbarkeit macht sie unverzichtbar für zahlreiche Branchen weltweit

Vakuumpumpenwelle ist eine Schlüsselkomponente in Vakuumpumpen, unerlässlich für Kraftübertragung, Effizienz und HaltbarkeitEs spielt eine entscheidende Rolle bei verschiedene Branchen, einschließlich Automobil-, Industrie-, Medizin- und HLK-Systeme, wodurch eine reibungslose und zuverlässige Leistung der Vakuumpumpe gewährleistet wird.

Shenchi Technology Co. ist ein professioneller OEM-Maschinenfabrik Sitz in Wenling, Zhejiang, China. Das Hauptgeschäft umfasst CNC-Dreh- und Frästeile, CNC-Bearbeitungszentrumsteile usw. Wir können die Formherstellung, Logoanpassung und Endbearbeitungsdienste wie Sandstrahlen, Pulverbeschichten, Eloxieren, Galvanisieren, Polieren und Laserätzen durchführen.

Jetzt abonnieren

Verpassen Sie keine zukünftigen Updates! Abonnieren Sie uns noch heute!

© Shenchi Company. Alle Rechte vorbehalten.