- WENLING ZHEJIANG CHINA

- [email protected]

- 86 18958695512

- Heim

- PRODUKT

- Andere Produktkomponenten

- Seiten

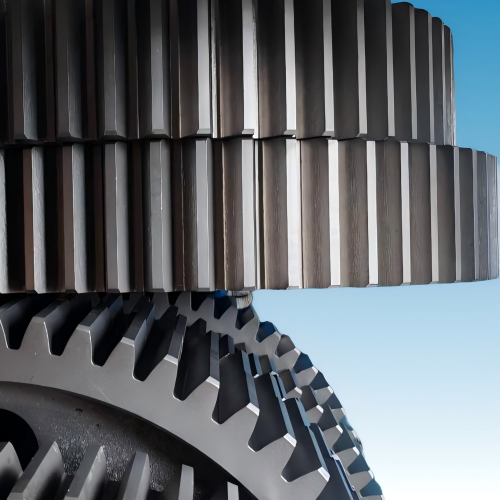

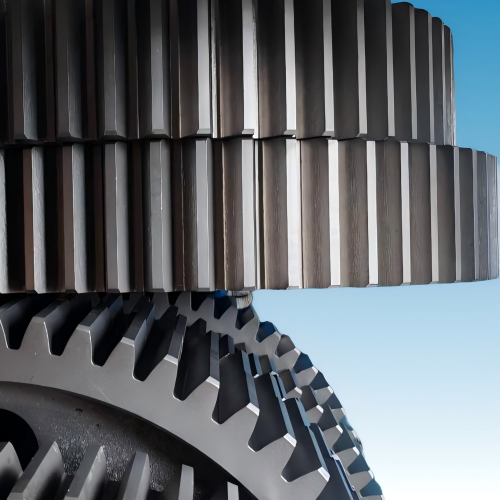

- Heavy Transmission Gear Parts Custom High Quality OEM Parts

Heavy Transmission Gear Parts Custom High Quality OEM Parts

In modern heavy industries, reliability and efficiency are everything. Whether you’re running a mining operation, cement plant, steel mill, or wind farm, your equipment depends on one critical element—heavy transmission gear parts. These components are responsible for transferring massive amounts of torque, ensuring smooth operation, and reducing downtime in even the harshest working environments.

At the core of this system are transmission gears Und big gears, which handle high loads and operate continuously under extreme pressure. As a professional gear manufacturer and exporter, we specialize in the production and customization of precision-engineered gear parts for global industrial applications.

NAME: Heavy Transmission Gear Parts

MODEL:SC205GR4124

MATERIAL: FOLGEN SIE IHREN ANFORDERUNGEN

MOQ: ALS IHRE ANFORDERUNG

LIEFERUNG: NACH IHRER MENGE

BEISPIEL: ANGEBOTENES MUSTER

URSPRUNGSORT: ZHEJANG, CHINA

SERVICE: OEM ODM ANGEPASST

VORTEIL: PROFESSIONELLES TEAM HOHE QUALITÄT

Heavy Transmission Gear Parts: Precision Components for Reliable Power Transmission

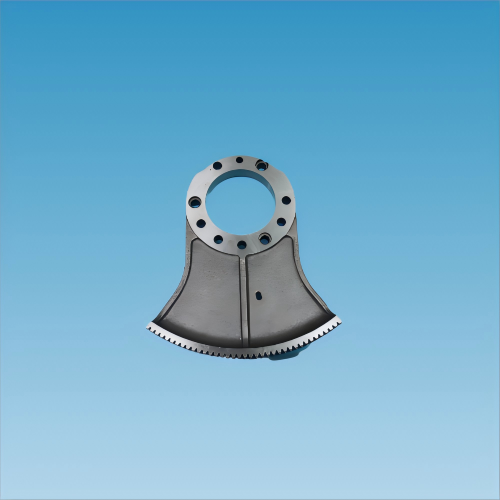

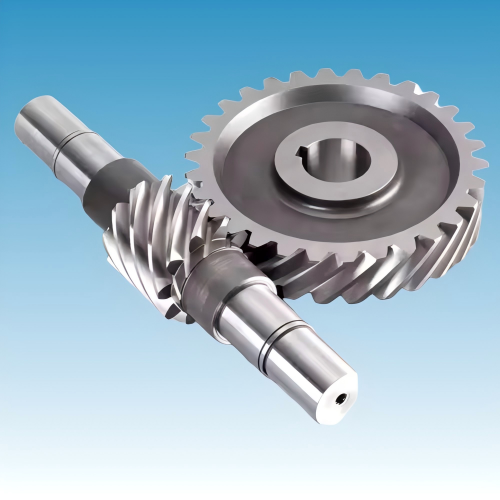

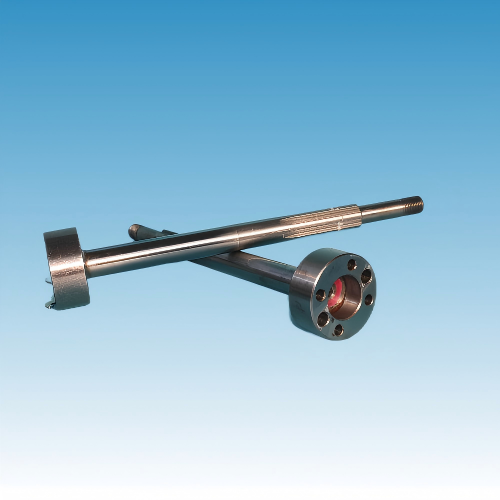

In the modern industrial world, power transmission is the heart of machinery. From heavy-duty mining equipment to high-performance marine engines and automated manufacturing systems, the need for high-precision, durable, and efficient transmission gear parts has never been greater. Among these, components like ring gears, shafts, pinions, and large-diameter gears form the core of systems that move heavy loads and convert power reliably.

As an experienced manufacturer and exporter of heavy transmission gear parts, we specialize in providing customized solutions that meet the highest demands of performance, precision, and durability. This article introduces the core categories of heavy transmission gear parts, highlights our production strength, and explains why global buyers trust us to deliver premium-quality gear components, including ring gear for reduction gear box applications.

Understanding Heavy Transmission Gear Parts

Heavy transmission gear parts are mechanical components used to transfer motion and torque in large-scale machinery and equipment. These parts are designed to operate under extreme stress, high torque, and continuous duty cycles. They are integral to gearboxes, drive systems, winches, turbines, and industrial reducers across a wide range of sectors.

Common Components Include:

Ring gears

Stirnräder

Schrägverzahnte Zahnräder

Kegelräder

Schneckengetriebe

Gear shafts

Planetary carriers

Slewing bearings

Reduction gear box assemblies

Each part must be engineered with a high level of precision, especially for high-load, low-speed applications, where improper gear meshing or tolerance mismatches can lead to early failure, vibration, and loss of efficiency.

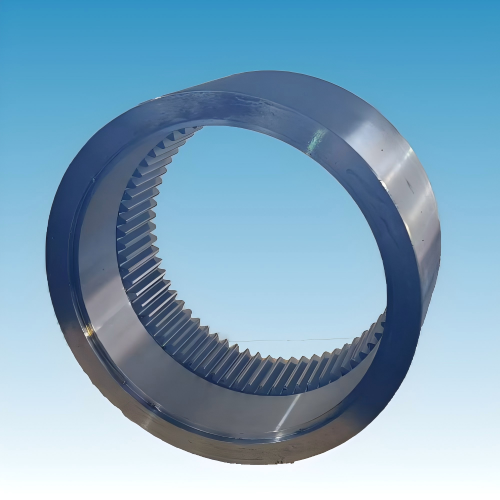

Ring Gear – A Key Component in Power Transmission

One of the most critical gear parts in modern gearboxes is the ring gear. A ring gear is a circular gear with teeth on either its internal or external circumference. It is commonly used in reduction gear boxes, especially in planetary gear systems, where it interacts with planet gears and a sun gear to produce high torque at reduced speed.

Key Functions of Ring Gears:

Torque multiplication

Load sharing among multiple gears

Noise and vibration reduction

Compact and high-power-density design

When buyers look for a ring gear for reduction gear box, they often need custom solutions based on load requirements, speed ratio, and gearbox layout. Our factory specializes in the design, machining, and quality control of such parts, with complete traceability and dimensional accuracy.

Applications of Heavy Transmission Gear Parts

Our heavy transmission gear parts are used in a variety of demanding environments:

Mining and Quarry Equipment: Crushers, mills, excavators

Cement Plants: Rotary kilns, ball mills, gear reducers

Steel Plants: Rolling mill drives, continuous casting lines

Wind Energy: Wind turbine main drives, yaw drives

Schifffahrtsindustrie: Propulsion systems, winches, deck machinery

Power Generation: Hydro turbines, gear couplings

Oil & Gas: Drilling rig gearboxes, pipe handling systems

Construction Machinery: Tower cranes, hoists, conveyors

In each of these sectors, the reliability of transmission gear parts is directly related to operational safety and equipment uptime. Poor-quality gears can result in costly repairs, unexpected downtime, and serious safety risks.

Precision Manufacturing Capabilities

Our reputation as a leading Chinese supplier of precision ring gear and transmission components is built on strong production capabilities and international quality assurance.

1. Advanced Equipment

CNC vertical lathes (up to 6 meters diameter)

CNC gear hobbing and shaping machines

Gear grinding machines for high-precision finishing

Heat treatment furnaces: carburizing, quenching, nitriding

3-axis and 5-axis machining centers

2. Materials Used

We select premium-grade materials according to customer requirements:

42CrMo, 40CrNiMo, 35CrMo

Carbon steel and alloy steel (normalized, quenched, tempered)

Cast steel or forged blanks for large gear rings

Material certificates and mechanical property tests are available with every shipment.

3. Wärmebehandlung

Proper heat treatment is essential to achieving the desired hardness and wear resistance. We offer:

Induction hardening for specific gear teeth zones

Carburizing and quenching for surface hardness (HRC 58–62)

Tempering to relieve internal stress

4. Precision and Tolerance Control

DIN 6–8 tooth profile accuracy

≤ 0.03 mm runout tolerance for ring gears

Full dimensional inspection using CMMs, gear testers, and hardness testers

Customized Gear Solutions

Every application is different. That’s why we offer customized transmission gear parts according to:

Customer drawings or 3D models

Specific torque and speed requirements

Working environment (temperature, lubrication, corrosion)

Special surface treatment (phosphating, black oxide, chrome coating)

Für ring gear for reduction gear box, we tailor tooth profiles (spur, helical, or double-helical), tooth modules, and face widths to achieve optimal meshing and performance.

Why Precision Matters

Precision isn’t just a buzzword—it is critical to the longevity and efficiency of any power transmission system.

The Importance of Precision Gear Parts:

Reduced Wear & Tear: Better gear meshing extends lifespan

Lower Noise: Precision gears reduce vibration and noise in operation

Energy Efficiency: Less backlash and smoother rotation improves power usage

Lower Maintenance Cost: Fewer breakdowns and minimal corrective maintenance

Especially for ring gear components that interface with multiple gears inside reduction gearboxes, even small inaccuracies can lead to accelerated wear or tooth breakage.

Our Advantages for Global Gear Buyers

OEM & ODM Capabilities

We serve both OEM customers and aftermarket buyers. Our engineering team can reverse-engineer old parts or help design new gear systems.

Strict Quality Control

Our ISO 9001-certified process includes incoming material inspection, in-process checks, and final inspection before packing. Third-party inspection is welcomed.

Global Export Experience

We supply to over 30 countries, including:

Germany

Italy

Russia

South Korea

Brazil

South Africa

United States

Export documents (CO, FTA, CE, etc.) and shipping terms (FOB, CIF, DDP) are handled smoothly.

Responsive After-Sales Support

If any issue arises, our technical team can respond within 24 hours. We also offer installation guidance and operational advice.

Buyer Tips: How to Choose the Right Transmission Gear Supplier

Check Technical Capabilities: Can they meet your tolerance and heat treatment needs?

Review Material and Testing Standards: Are materials certified? Is ultrasonic or hardness testing included?

Ask for Gear Accuracy Grades: DIN, AGMA, or ISO classifications define performance.

Evaluate Lead Time: Choose a supplier with flexible production to reduce downtime.

Insist on Customization: Off-the-shelf parts often won’t fit well in custom-built gearboxes.

Conclusion: Reliable Supplier for Precision Ring Gear and Heavy Gear Parts

If you’re looking for a precision gear manufacturer who can deliver ring gear for reduction gear box and other heavy-duty transmission components with consistent quality, competitive pricing, and reliable service, we’re your ideal partner.

We understand what global mechanical parts buyers need: clear communication, on-time delivery, and zero compromise on technical accuracy. With over a decade of experience and a fully equipped manufacturing base, we ensure every gear that leaves our facility exceeds expectations.

Whether you’re in need of one-time spare parts or long-term bulk procurement, we welcome your inquiries. Send us your drawings, RFQs, or technical specs today—and let us help drive your machines forward.

Shenchi Technology Co. ist ein professioneller OEM-Maschinenfabrik Sitz in Wenling, Zhejiang, China. Das Hauptgeschäft umfasst CNC-Dreh- und Frästeile, CNC-Bearbeitungszentrumsteile usw. Wir können die Formherstellung, Logoanpassung und Endbearbeitungsdienste wie Sandstrahlen, Pulverbeschichten, Eloxieren, Galvanisieren, Polieren und Laserätzen durchführen.

Jetzt abonnieren

Verpassen Sie keine zukünftigen Updates! Abonnieren Sie uns noch heute!

© Shenchi Company. Alle Rechte vorbehalten.