- WENLING ZHEJIANG CHINA

- [email protected]

- 86 18958695512

- Home

- PRODUCT

- Contruction machinery components

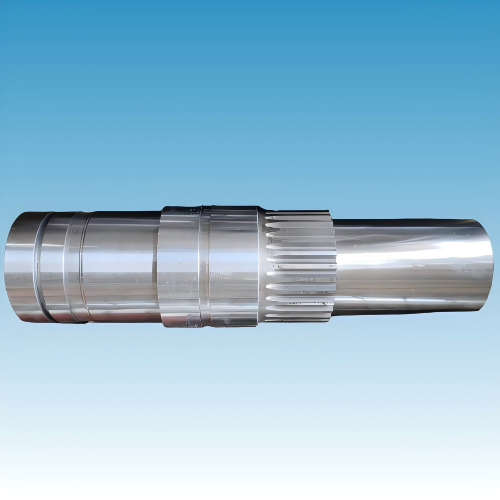

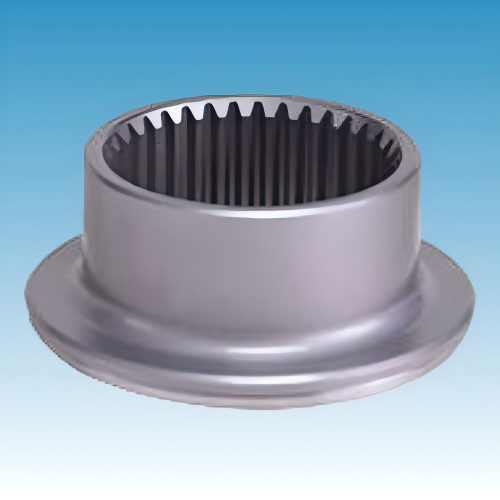

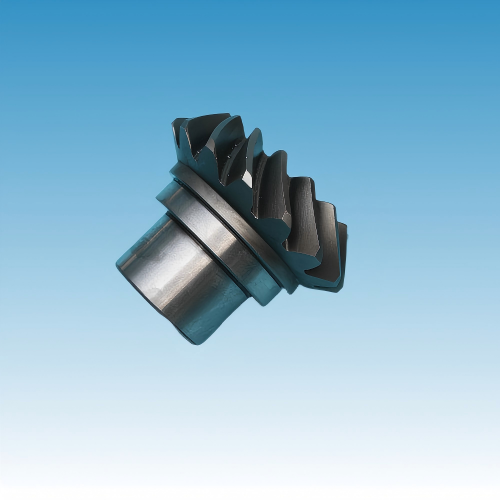

- Bevel gear high precision crown gear accurate miner fitting

Bevel Gear High Precision Crown OEM Small miner fitting

Bevel Gear High Precision Crown Wheel Bevel gear OEM Small metel Pinion Gear Part Forging Hobbing Straight Screw Spur Spiral Bevel Helical Pinions miner fitting

SC205GC5005

bevel gear is a type of gear used to transmit rotary motion between two shafts that are typically set at a right angle (90 degrees) to each other, although other angles are also possible. Bevel gears are shaped like cones or pyramids, with their teeth angled in such a way that they mesh smoothly with another gear, allowing for the transfer of motion between non-parallel shafts.

NAME: BEVEL GEAR

MODEL: SC205GC5005

MATERIAL:STEEL,COPPER

MOQ: AS YOUR REQUIREMENT

DELIVERY: ACCORDING TO YOUR QUANTITY

SAMPLE: SAMPLE OFFERED

ORIGIN PLACE: ZHEJANG CHINA

SERVICE: OEM ODM CUSTOMIZED

ADVANTAGE: PROFESSIONAL TEAM HIGH QUALITY

Key features of bevel gears

- Teeth Angled: The teeth of bevel gears are cut along the cone’s surface and typically meet at the apex of the cone. This angle allows them to engage efficiently, even when the shafts are not parallel.

- Conical Shape: They have a conical or tapered shape, where the gear’s diameter decreases towards the center, resembling a portion of a cone.

- Right-Angle Operation: they are designed to work at right angles (90 degrees), making them ideal for applications like turning the direction of motion from one shaft to another.

Straight

- Teeth are straight and extend from the center of the gear to the edge.

- Common in simpler applications where smoothness of operation is less critical.

Spiral

- Teeth are curved or spiral, which allows for smoother, quieter, and more efficient operation compared to straight bevel gears.

- Spiral gears are often used in more complex or high-performance applications, such as in automotive and aerospace systems.

Hypoid

- Similar to spiral bevel gears, but the axes of the gears are offset, meaning the shafts do not intersect.

- This type of gear is commonly used in car differentials because of its ability to handle high loads and provide smoother operation.

Miter

- A special kind of this where both gears in the pair have the same size (same number of teeth), often used in applications where equal torque distribution is required.

- Automobiles: Used in the drivetrain, especially in differentials, to change the direction of the power from the engine to the wheels.

- Aerospace: they are used in aircraft engines and other systems requiring a change in the angle of motion.

- Industrial Machinery: Used in gearboxes, conveyors, and other systems that require the transfer of motion at an angle.

- Marine Systems: Common in the drive systems of boats or ships to direct power from the engine to the propellers.

they are particularly useful when a system needs to transfer motion or power between shafts that are not parallel to each other, and they help facilitate efficient operation in these types of mechanical systems.

it is a type of gear used to transmit rotary motion between two shafts that are typically set at a right angle (90 degrees) to each other, although other angles are also possible. they are shaped like cones or pyramids, with their teeth angled in such a way that they mesh smoothly with another gear, allowing for the transfer of motion between non-parallel shafts.

Shenchi technology co.,is a professional OEM machinery factory located in Wenling zhejiang,China. The main business includes CNC turning and milling parts, CNC machining center parts, etc.We can complete the mold product, logo customization and finish services including sandblasting, powder coating, anodizing, electroplating, polishing and laser etching.

© Shenchi Company All Rights Reserved.