- WENLING ZHEJIANG CHINA

- [email protected]

- 86 18958695512

- Home

- PRODUCT

- Other products components

- Machinery Eccentric sleeve custom for Various Applications

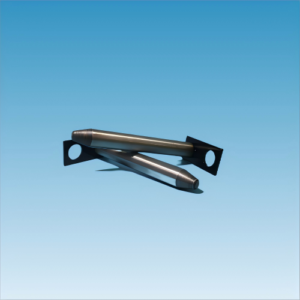

Machinery Eccentric Sleeve Custom For Various Applications

Machinery Eccentric Sleeve Milling Turning Drilling Components OEM EDM Custom CNC Machining Parts

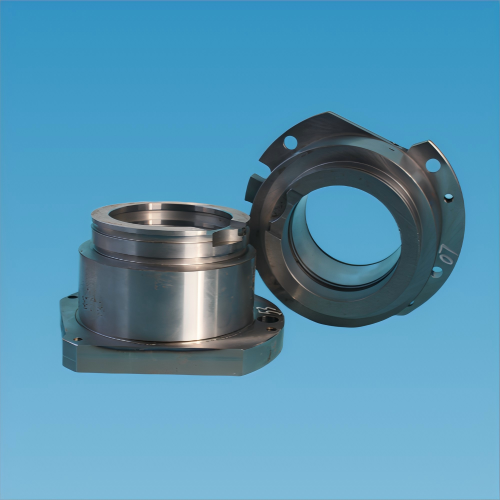

Precision Engineering Sleeve Bearing High-Performance Precision Axle Sleeve for Various Applications

SC205QT5044

Eccentric sleeve are specialized mechanical components used in various machinery to convert rotary motion into oscillating or reciprocating motion. Unlike traditional gears, which have a centered rotation axis, eccentric gears have an off-center axis, allowing them to create a non-uniform movement pattern. This unique design is beneficial in many industrial applications where precise motion control is required.

NAME:Eccentric sleeve

MODEL: SC205QT5044

MATERIAL:STEEL

MOQ: AS YOUR REQUIREMENT

DELIVERY: ACCORDING TO YOUR QUANTITY

SAMPLE: SAMPLE OFFERED

ORIGIN PLACE: ZHEJANG CHINA

SERVICE: OEM ODM CUSTOMIZED

ADVANTAGE: PROFESSIONAL TEAM HIGH QUALITY

Machinery Eccentric sleeve

Eccentric sleeves are specialized mechanical components used in various machinery to convert rotary motion into oscillating or reciprocating motion. Unlike traditional gears, which have a centered rotation axis, eccentric gears have an off-center axis, allowing them to create a non-uniform movement pattern. This unique design is beneficial in many industrial applications where precise motion control is required.

These gears play a crucial role in automated machinery, textile machines, robotics, medical equipment, and heavy-duty industries, contributing to the efficiency and performance of mechanical systems.

How Machinery Eccentric Sleeve

Eccentric gears function by using an off-center gear rotation, which leads to varying speeds and movement patterns within a mechanical system. The eccentric motion helps convert continuous rotary motion into controlled oscillations, making them useful for pumping mechanisms, vibrating systems, and cam-driven applications.

The gear’s unique structure consists of:

- Eccentric Shaft – A shaft whose axis does not align with the center of the gear.

- Gear Teeth – The gear teeth engage with other gears or mechanical components to transfer motion.

- Bearing or Bushings – Used to reduce friction and ensure smooth rotation.

As the eccentric gear rotates, the off-centered motion creates a variable output, enabling applications such as reciprocating pumps, textile weaving machines, and automation systems.

Key Features of Machinery Eccentric sleeve

✔ Off-Center Rotation – Provides variable speed and motion patterns suitable for oscillating or reciprocating applications.

✔ Durable & High-Strength Materials – Typically made from hardened steel, alloy steel, brass, or aluminum for long-lasting performance.

✔ Smooth Motion Control – Ensures precise movement, reducing vibrations and increasing stability in mechanical operations.

✔ Highly Versatile – Used in industrial machines, automotive systems, robotics, and high-precision applications.

Applications of Machinery Eccentric Sleeve

Industrial Automation & Robotics

- Eccentric gears are widely used in automated assembly lines, robotic arms, and conveyor belt systems.

- They enable precise movement, controlled vibrations, and efficient load distribution.

Textile & Printing Machines

- Used in fabric weaving, embroidery, and printing machinery for smooth, oscillating movement.

- Enhances the accuracy and speed of textile manufacturing processes.

Automotive & Engine Components

- Found in Wankel rotary engines, camshaft systems, and valve control mechanisms.

- Helps regulate fuel injection, valve timing, and rotational balance.

Mechanical Presses & Stamping Machines

- Eccentric gears provide precise force distribution in metal stamping, punching, and cutting machines.

- Essential for industries that require high-speed, precision manufacturing.

Pumps & Fluid Handling Equipment

- Used in reciprocating pumps, diaphragm pumps, and peristaltic pumps.

- Ensures smooth and controlled fluid movement, minimizing pressure fluctuations.

Medical & Laboratory Equipment

- Applied in MRI machines, blood analyzers, and robotic surgical tools.

- Provides precise movement in high-accuracy medical instruments.

Vibrating Machinery & Conveyors

- Used in vibrating screens, feeders, and sorting equipment.

- Generates controlled vibration for material handling.

Advantages of Machinery Eccentric Sleeve

✔ Efficient Motion Conversion – Ideal for applications requiring rotary-to-linear transformation.

✔ Durability & High Load Capacity – Engineered to handle heavy-duty operations and prolonged use.

✔ Precision & Stability – Reduces mechanical stress and ensures smooth motion control.

✔ Versatile Applications – Found in industrial, automotive, medical, and textile industries.

Conclusion

Eccentric sleeves are vital components in modern machinery, offering precision, versatility, and durability in a wide range of applications. Their ability to convert rotary motion into oscillating or reciprocating movement makes them indispensable in industries such as automation, automotive, textile, and medical equipment.

With continuous advancements in gear technology and material engineering, eccentric gears continue to play a crucial role in enhancing efficiency, accuracy, and performance in industrial machinery worldwide. ⚙️🚀

Shenchi technology co.,is a professional OEM machinery factory located in weneling zhejiang,China. The main business includes CNC turning and milling parts, CNC machining center parts; etc.We can complete the mold product, logo customization and finish services including sandblasting, powder coating, anodizing, electroplating, polishing and laser etching.

©2024. Shenchi Company All Rights Reserved.