- WENLING ZHEJIANG CHINA

- [email protected]

- 86 18958695512

- Home

- PRODUCT

- Other products components

- Swing arm gear high density and strength transmission system

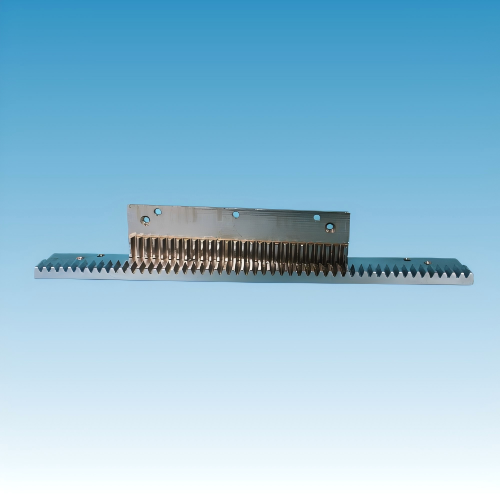

Swing arm gear high density and strength transmission system

Swing arm gear with high density and strength for transmission systems factory direct sale for CNC swing arm gear custom adjustable Tension Extended Rear gears

SC205QT3025

A swing arm gear is a specialized mechanical component used in systems that incorporate a swing arm mechanism. A swing arm is typically a pivoting or oscillating arm that moves around a fixed point to control or transfer motion within a machine. The swing arm gear, integrated into this system, is designed to transmit power and regulate the movement of the swing arm, converting rotary motion into controlled angular or reciprocating motion.

NAME:Swing arm gear

MODEL: SC205QT3025

MATERIAL:AS YOUR REQUIREMENT

MOQ: AS YOUR REQUIREMENT

DELIVERY: ACCORDING TO YOUR QUANTITY

SAMPLE: SAMPLE OFFERED

ORIGIN PLACE: ZHEJANG CHINA

SERVICE: OEM ODM CUSTOMIZED

ADVANTAGE: PROFESSIONAL TEAM HIGH QUALITY

Swing arm gear application

Key Features

Off-Center or Offset Design:

The gear is mounted on a shaft in such a way that its rotational axis is not aligned with the center of the gear’s body. This offset configuration enables the conversion of uniform rotary motion into a variable, oscillating movement.Precision Engineering:

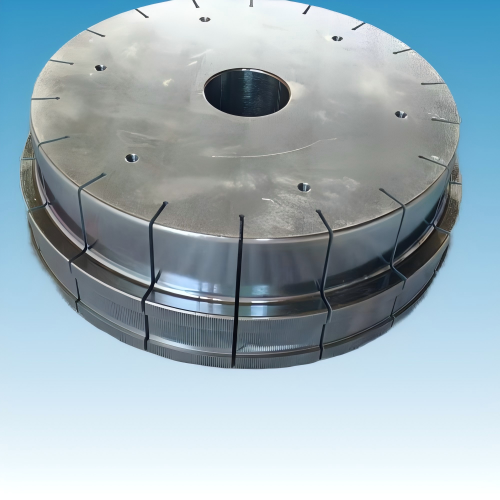

Manufactured with tight tolerances using CNC machining or other high-precision techniques, the swing arm gear ensures smooth engagement with other gears or linkages. Precision is essential to avoid vibration and ensure accurate motion control.Robust Materials:

Swing arm gears are typically made from durable materials such as hardened steel, alloy steel, or brass. The material choice depends on the operational load, environmental conditions, and the required lifespan of the gear.Smooth Power Transmission:

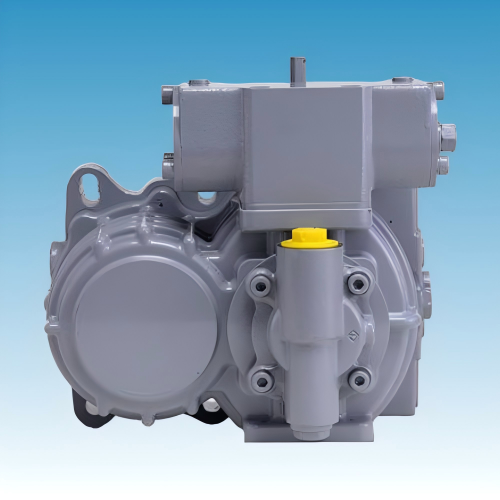

Designed to work seamlessly with related components like shafts, bearings, and coupling devices, the gear efficiently transfers rotational energy to the swing arm. This results in a controlled oscillation or reciprocating motion used in various machine functions.

How It Works

Motion Conversion:

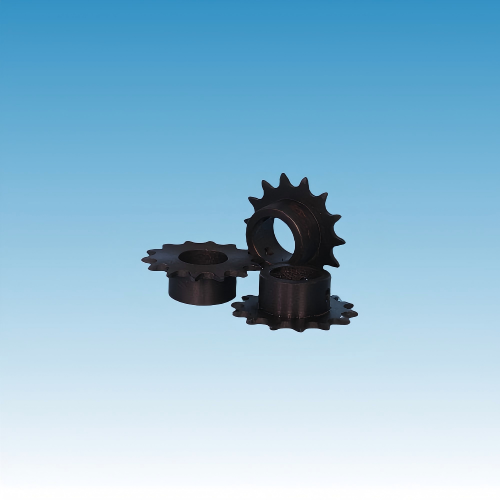

When the gear rotates (powered by an electric motor or engine), its off-center design creates an uneven force distribution. This non-uniform motion causes the swing arm, which is connected to the gear via mechanical linkages, to oscillate or reciprocate. This mechanism is crucial in applications where controlled linear or angular movement is needed.Interfacing with Other Components:

The swing arm gear meshes with other gears or mechanical components, such as racks, pinions, or cam systems, to achieve the desired motion. Its design is tailored to ensure consistent engagement and reliable performance even under continuous operation.

Applications

Industrial Machinery:

Swing arm gears are frequently found in automation systems, vibratory screens, and conveyor systems. In these systems, they regulate the swinging or oscillating motion that is critical for material handling and sorting.Textile & Printing Machines:

In the textile industry, these gears are used to control the movement of components in spinning or weaving machines, ensuring that fabrics are processed with precise timing. Similarly, printing presses may use swing arm gears to control the motion of ink rollers and paper feeds.Automotive & Aerospace:

Some automotive components, such as certain engine or suspension systems, may incorporate swing arm gears to regulate movement. In aerospace or defense applications, these gears are employed in mechanisms that require precise oscillatory motion.Robotics & Medical Equipment:

In robotics, swing arm gears can be used in the joints or arms to achieve controlled, repeatable movement. Similarly, high-precision medical devices, like certain types of surgical tools or diagnostic instruments, may utilize these gears to ensure accurate motion control.

Advantages

Precise Control:

The off-center design allows for exact conversion of rotary to reciprocating motion, which is essential for precision applications in industrial and high-tech equipment.Durability and Reliability:

Constructed from high-strength materials and manufactured with tight tolerances, swing arm gears are built to last and withstand significant mechanical stress.Versatility:

Their design makes them adaptable for a range of applications—from heavy-duty industrial machinery to delicate medical instruments.Efficiency:

By converting motion with minimal energy loss and vibration, these gears enhance the overall efficiency of the system in which they are used.

Conclusion

A swing arm gear is a critical component in many mechanical systems, engineered to convert rotary motion into controlled, oscillatory movement. With features such as an off-center design, precision machining, and durable construction, these gears play a vital role in ensuring the smooth operation of industrial machinery, automotive systems, textile equipment, robotics, and more. Their ability to deliver precise motion control while handling significant loads makes them indispensable in a wide range of high-performance applications.

Shenchi technology co.,is a professional OEM machinery factory located in Wenling zhejiang,China. The main business includes CNC turning and milling parts, CNC machining center parts, etc.We can complete the mold product, logo customization and finish services including sandblasting, powder coating, anodizing, electroplating, polishing and laser etching.

© Shenchi Company All Rights Reserved.